Composite Outdoor Seating

Width: 80mm

Thickness: 40mm

Color: Coffee, Chocolate, Wood, Red Wood, Cedar, black, Gray, or customized

Recycling: totally eco-friendly, 100% recycling

Application: garden furniture, park, outdoor, patio, courtyard, etc

Surface Treatment: Sanding

After-sale service: Online technical support

Maintenance: Requires no painting, no glue, low maintenance

WPC Outdoor Seats (Composite Outdoor Seating) : Functional Outdoor Leisure Equipment Adaptable to All Scenarios

With the popularization of outdoor lifestyles, the demand for seats in scenarios such as courtyards, terraces, campsites, scenic trails, and commercial outdoor seating areas is no longer limited to the basic function of "sitting", but also pursues the triple values of "scenario adaptability, functional diversity, and environmental integration". However, WPC Outdoor Seats (Composite Outdoor Seating), relying on material innovation and functional design, have become the preferred choice to break this limitation. Traditional outdoor seats are either limited by materials and difficult to cope with complex climates, or unable to meet the needs of diverse scenarios due to single design. They not only retain the natural texture of wood, but also have the weather resistance of plastic, and through modular functional design, adapt to the full-scenario needs from family private leisure to commercial public services, creating an "one place, one seat; one seat, multiple uses" outdoor leisure experience for users, and redefining the practical value and aesthetic expression of outdoor seats.

Major Advantages of the Product

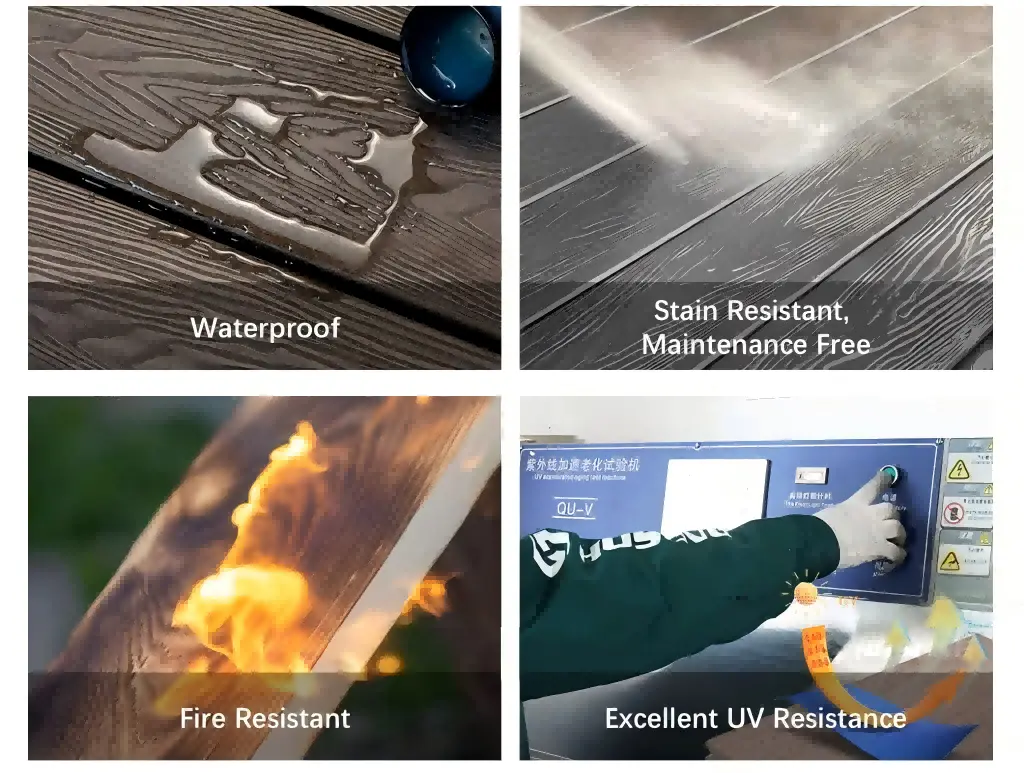

✅ All-Scenario Climate Adaptability and Damage Resistance

Composite Outdoor Seating are specially optimized for different outdoor climate scenarios, forming a "global weather resistance system". In high-temperature and high-humidity southern regions, anti-mildew ingredients are added to the material to prevent the growth of mold caused by long-term humidity; in dry and windy northern regions, high-density composite technology is adopted to prevent the material from cracking due to water loss; in high-altitude areas with strong ultraviolet rays, the surface is covered with three layers of anti-UV coating, with an ultraviolet blocking rate of more than 95%, and no fading after long-term exposure; in the face of extreme weather such as hail and heavy rain, the seat body adopts a "reinforced honeycomb structure", and the impact resistance is 30% higher than that of ordinary WPC products, and it is not easy to dent or break. In addition, the material itself does not absorb water or moisture, and there is no residual water after snow melts in winter, avoiding damage to the seat caused by freeze-thaw cycles, and realizing stable use in "all weather and all regions".

✅ Functional Modularity and Scenario Adaptability Flexibility

It adopt a combined design of "basic seat body + functional modules", and users can freely match accessories according to scenario needs to achieve functional customization. In the family courtyard scenario, you can add a "side storage module" (for storing outdoor tea sets and magazines) and a "detachable sunshade" (for sun protection and rain protection); in the camping scenario, it is equipped with a "foldable backrest" (which can be used as a temporary small table after folding) and a "hidden hook" (for hanging backpacks and clothes); in the commercial outdoor seating scenario, you can choose to install an "embedded charging interface" (supporting wireless mobile phone charging) and "LED ambient light strips" (for night lighting and atmosphere creation); in the scenic trail scenario, it is matched with a "first aid kit storage box" (with basic medical supplies inside) and a "solar warning light" (for prompting pedestrians at night). This modular design not only meets the functional needs of different scenarios, but also supports later functional upgrades without replacing the entire seat, reducing the use cost.

✅ Environmental-Friendly Materials and Ecological Integration

The raw materials of it adopt a composite formula of "60% recycled wood fiber + 30% recycled plastic + 10% plant fiber". Among them, recycled wood fiber comes from furniture production waste and forest thinning wood, and recycled plastic comes from waste agricultural film and packaging materials. Producing a set of standard it can reduce 1.2kg of plastic waste and save 0.6 cubic meters of wood. The production process adopts a "non-high-temperature melting process", which reduces energy consumption by 40% compared with traditional plastic seats, and has no waste gas or waste water emissions. At the same time, the seat color uses natural plant dyes, which can be naturally degraded after fading, without polluting the soil and water sources. In addition, the surface texture of the material imitates the annual rings and texture of natural wood, and there is no sense of violation when matching with outdoor green plants, rocks and other environmental elements, realizing the ecological integration effect of "seat is landscape", and avoiding the visual conflict between traditional metal or plastic seats and the natural environment.

✅ Low-Intervention Maintenance and Long-Term Economy

The maintenance of it follows the principle of "low intervention and zero maintenance", and no professional maintenance measures are required in daily use. Surface stains can be removed by simply wiping with a damp cloth, and stubborn stains such as oil and sauce can be easily removed after soaking in soapy water, without using strong corrosive detergents; if there are local scratches after long-term use, they can be restored to their original appearance by gently sanding with fine sandpaper, without repainting; the material itself has no insect infestation or decay problems, and no regular application of insect repellents or preservatives is required. From the perspective of long-term use cost, the service life of it can reach more than 20 years, and the maintenance cost during this period is less than 1/10 of that of traditional solid wood seats. Moreover, unlike metal seats, there is no need for regular rust removal and part replacement, and the comprehensive cost performance is far higher than that of traditional outdoor seats.

✅ Ergonomics and Safety Protection Design

The seat curve of Composite Outdoor Seating has undergone "dynamic ergonomic testing", and is optimized for different usage postures (sitting posture, semi-reclining posture, side leaning posture): the seat width is designed according to the hip width of 95% of adults (standard width 55cm) to avoid discomfort caused by narrowness; the backrest curve fits the natural curve of the human spine, and the waist support height reaches 18cm, with no backache after long sitting; the armrest height is set to 72cm, which conforms to the comfortable height when the arms are naturally hanging, and there is no pressure when placing the elbows. In terms of safety protection, all edges and corners of the seat body adopt "R5mm rounded corner treatment" to avoid collision injuries; the edge of the seat surface is provided with "anti-slip raised strips" to prevent the body from slipping when getting up; in the children's exclusive style, "anti-slip suction cups" are added at the bottom of the seat legs to fix on the ground and prevent tipping. At the same time, the seat spacing is controlled within 15cm to prevent children's fingers from being pinched, ensuring all-round use safety.

Application of More Than Ten Colors

Composite Outdoor Seating have sixteen basic colors and four special process colors, which can accurately match the aesthetic needs and functional positioning of different scenarios. In natural ecological scenarios (such as forest parks and wetland parks), colors such as light birch, dark oak, and moss green can be deeply integrated with the natural environment, highlighting the ecological atmosphere; in modern minimalist scenarios (such as villa terraces and commercial complex outdoor seating areas), neutral colors such as glacier white, light gray, and carbon black are matched with metal texture accessories to show a simple and high-end sense; in dynamic leisure scenarios (such as campsites and children's playgrounds), bright colors such as sunset orange, mint blue, and lemon yellow can stimulate the vitality of the space and attract users to stay; in traditional cultural scenarios (such as ancient town scenic spots and Chinese-style courtyards), traditional color systems such as cinnabar red, dark cyan, and red sandalwood are matched with carved patterns to convey cultural charm. In addition, it supports customizations of special processes such as "color gradient" and "wood grain splicing". For example, "blue-white gradient" seats are designed for beach resort scenarios to simulate the visual effect of waves and beaches and enhance the scene atmosphere.

OEM and ODM Services

In response to the differentiated needs of global customers, we provide OEM and ODM services with "high customization and fast response speed". In terms of OEM services, customers can provide brand logos, size parameters, color standards, and functional accessory requirements. We rely on automated production lines to achieve standardized production, supporting a minimum order quantity of 50 sets, with the shortest order cycle of 12 days. At the same time, we provide free logo laser engraving and screen printing services to ensure that the products are highly consistent with the customer's brand image. In terms of ODM services, the design team will conduct original designs based on the scenario characteristics, user needs, and cultural preferences of the customer's market. For example, "integrated sunshade and sun protection" seats are designed for Middle Eastern customers (adapting to high-temperature exposure environments), "winter warm armrest" seats are developed for Nordic customers (with heating plates built into the armrests), and "heavy rain prevention and drainage" seats are created for Southeast Asian customers (with hidden drainage holes designed in the seat body). During the design process, 3D model preview and 1:1 sample production services are provided, and customers can put forward modification suggestions until they are satisfied. The final products can also assist in passing the compliance certification of the local market to help customers quickly open the market.

Composite Outdoor Seating Installation Steps

✅ Preparation Before Installation

- Scenario Confirmation: Confirm the type of installation ground according to the seat usage scenario (hard ground such as cement ground and tile ground; soft ground such as grassland and sandy soil). For soft ground, a 10cm thick concrete cushion or anti-corrosion wood platform needs to be laid in advance to ensure that the ground flatness error is ≤3mm.

- Tool and Accessory Inspection: Prepare tools such as electric drills, levels, tape measures, Phillips screwdrivers, expansion screws (for hard ground), and ground nails (for soft ground); unpack and check whether the seat components (seat body, functional modules, screw packs, installation instructions) are complete and whether there is any transportation damage.

✅ Installation of the Basic Seat Body

- Installation on Hard Ground: Use a tape measure to determine the installation position and mark the screw fixing points; drill holes on the ground with an electric drill (the hole diameter matches the expansion screw), insert the expansion screw and reserve a height of 5mm; align the installation hole at the bottom of the seat body with the expansion screw, tighten the nut with a wrench, and calibrate the seat body with a level during the process to ensure no inclination.

- Installation on Soft Ground: First, fix the concrete cushion or anti-corrosion wood platform on the ground, and mark the installation points on the cushion; connect the seat body to the cushion with self-tapping screws, and the screws need to penetrate the cushion by more than 5cm to ensure firm fixation without shaking.

✅ Assembly of Functional Modules

- Install the functional modules in sequence according to the installation instructions. For example, when installing the storage module, align the module buckle with the seat body slot, press gently until the buckle is locked, and then use screws for auxiliary fixation; when installing the charging module, first connect the module power cord (if it is a solar model, the solar panel needs to be fixed first), then embed the module into the reserved position of the seat body, and cover the screw hole with a decorative cover.

- After the module installation is completed, test whether the functions are normal: whether the storage module switch is smooth, whether the charging module can supply power normally, and whether the LED light strip can be lit normally, ensuring that all functional modules are used normally.

✅ Debugging and Acceptance

- Overall Debugging: Shake the seat body and functional modules by hand to check for looseness; sit on the seat to test comfort, adjust the backrest angle (if it is an adjustable model) to the most comfortable position; simulate outdoor usage scenarios to test the practicality of the functional modules (such as the capacity of the storage module and the load-bearing capacity of the hook).

- Cleaning and Acceptance: Wipe the surface of the seat with clean water to remove dust and fingerprints remaining during the installation process; check whether all screws are hidden or the decorative covers are installed in place to ensure a neat appearance; confirm that the installation position does not affect pedestrian traffic or block fire-fighting access, and it can be put into use after passing the acceptance.

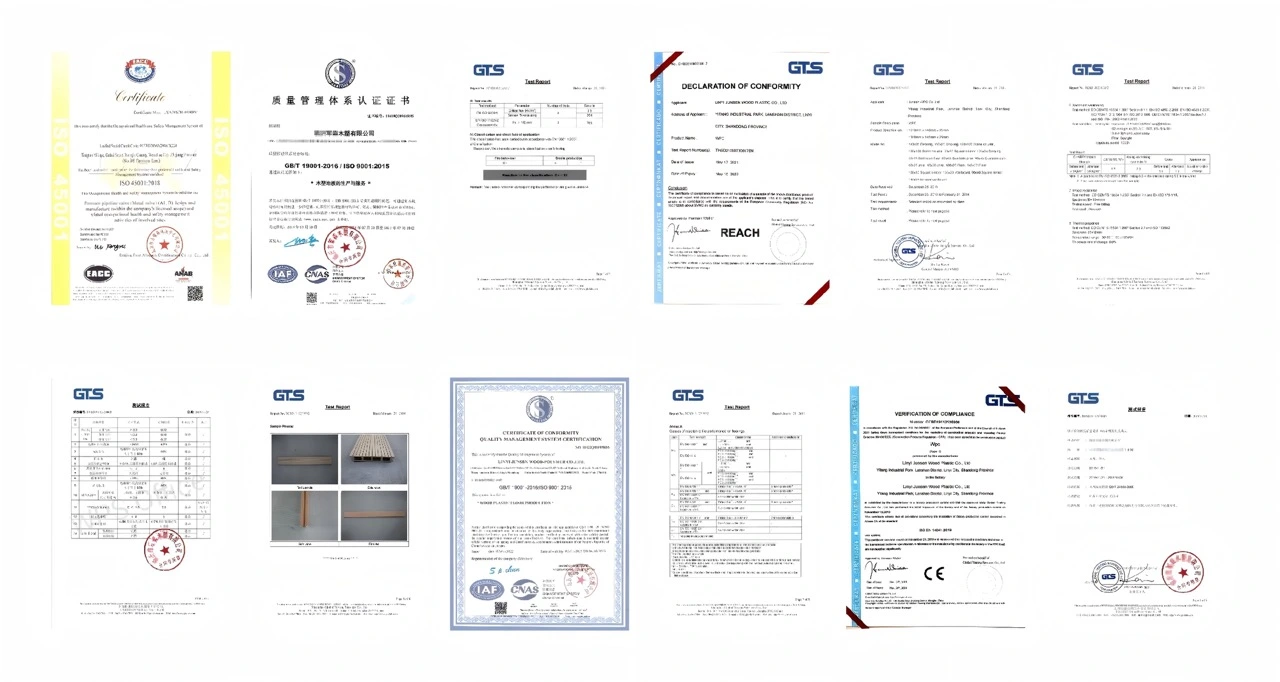

Relevant Qualification Certifications

To ensure product quality and market compliance, Composite Outdoor Seating have passed a number of domestic and foreign authoritative certifications and tests. In terms of international certifications, they have obtained the EU EN 1728 Outdoor Furniture Safety Certification (covering structural strength and fire performance tests), the US EPA Environmental Protection Certification (verifying that the material releases no toxic substances), and the Australian AS/NZS 4422 Outdoor Furniture Standard Certification (adapting to Australia's extreme climate); in terms of domestic certifications, they comply with the latest standard of GB/T 24137-2021 "Wood-Plastic Composite Panels" and the GB 6675-2014 "Toy Safety" standard (for children's styles). At the same time, they have passed the "weather resistance test", "formaldehyde emission test", and "load-bearing durability test" of the Forest Products Quality Supervision and Inspection Center of the National Forestry and Grassland Administration. Among them, the formaldehyde emission is far lower than the national standard (≤0.02mg/m³), and the load-bearing durability can withstand 100,000 cycles of loading without damage. These certifications are not only proof of product quality, but also a guarantee for customers to purchase and use with confidence.

Conclusion

With the core of "full-scenario adaptation, full-functional customization, and full-cycle durability", WPC Outdoor Seats (Composite Outdoor Seating) have broken the limitations of traditional outdoor seats with single functions and limited scenarios, and endow different outdoor spaces with more practical value and aesthetic possibilities. Whether it is family users creating an exclusive courtyard leisure corner, commercial customers building characteristic outdoor service scenarios, or scenic spots creating humanized leisure facilities, it can meet diverse needs with their unique material advantages, flexible functional design, and rich customization services. We always take "user scenario needs" as the starting point, continuously optimize product processes and service systems, and provide professional support throughout the entire process from design, production to installation, committed to making every product a "functional highlight" and "visual focus" of the outdoor space.

FAQ

1.How does product handle extreme weather?

Our WPC core and alloy frames resist UV damage, -30°C cold, and saltwater corrosion, ensuring decades of use without warping or fading.

2.Can I get custom colors for a 500-unit order?

Yes! We offer Pantone-matched finishes with a 3-day prototype turnaround.

3.Are your materials certified for eco-sensitive projects?

Absolutely. We're GREENGUARD Gold and FSC-certified, with 100% recycled content.

4.What's the ROI for product vs. wood?

Save $150/year on maintenance, with 3x longer lifespan—payback starts in Year 3.

Contact Us

📧 Email: info@durable-fences.com

📞 Phone: +86 18066962697

💬 WhatsApp: +86 18066962697

🟢 WeChat: +86 18066962697

Choosing WPC Outdoor Seats (Composite Outdoor Seating) is not only choosing a durable outdoor equipment, but also choosing a diverse, comfortable, and environmentally friendly outdoor lifestyle. It is believed that it will accompany you in every outdoor scenario to enjoy the beautiful time of nature and leisure.

Get a Quote for Your Fencing Project Today