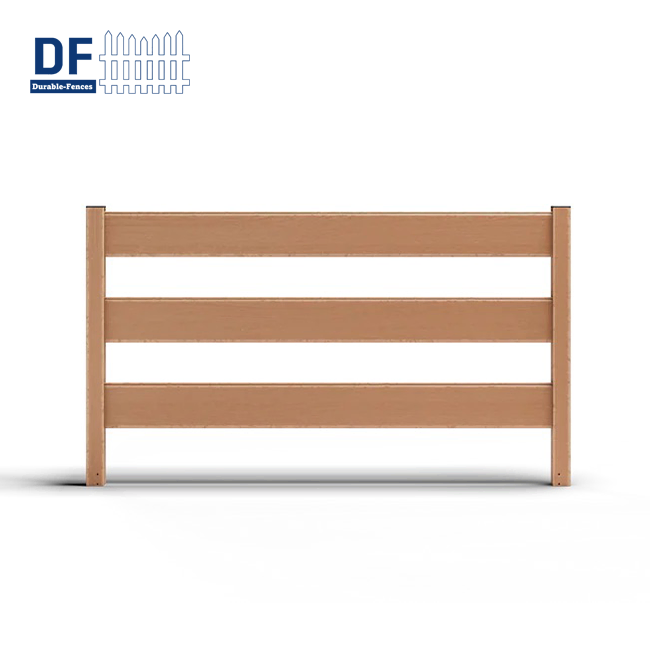

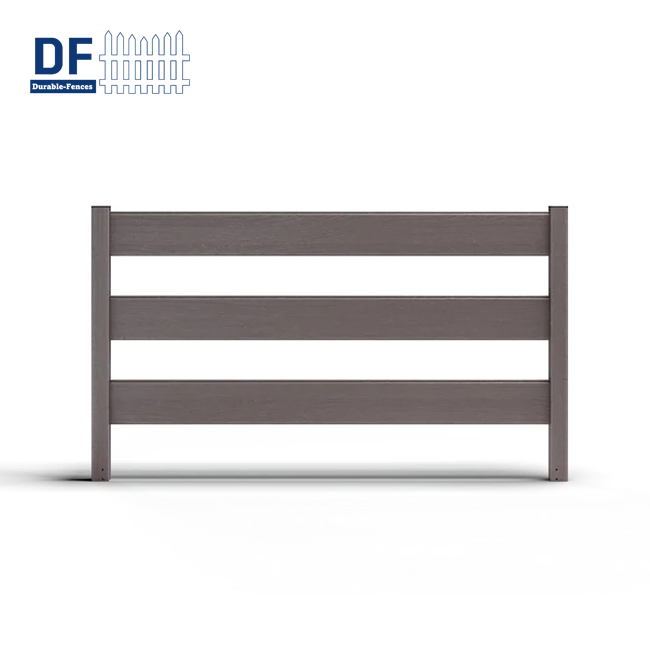

Composite Ranch Rail Fencing

Handrail: 60x40mm (2.36×1.57 inches), 80x40mm (3.15×1.57 inches), 90x45mm (3.54×1.77 inches), 100x50mm (3.94×1.97 inches), 105x50mm (4.13×1.97 inches), 160x80mm (6.30×3.15 inches), 200x80mm (7.87×3.15 inches), 200x100mm (7.87×3.94 inches),or customized

Beams: 35x35mm (1.38×1.38 inches), 40x40mm (1.57×1.57 inches), 60x40mm (2.36×1.57 inches), 60x60mm (2.36×2.36 inches), 73x73mm (2.87×2.87 inches), 80x80mm (3.15×3.15 inches),or customized

Length: customizable according to project needs

Material Composition: 60% recycled hardwood fibres+30% recycled polyethylene plastic(Grade A)+10% Additives (UV inhibitors, stabilizers, anti-slip treatments)

Surface: Normal,Brushed,Embossed,Co-extrusion,or customized

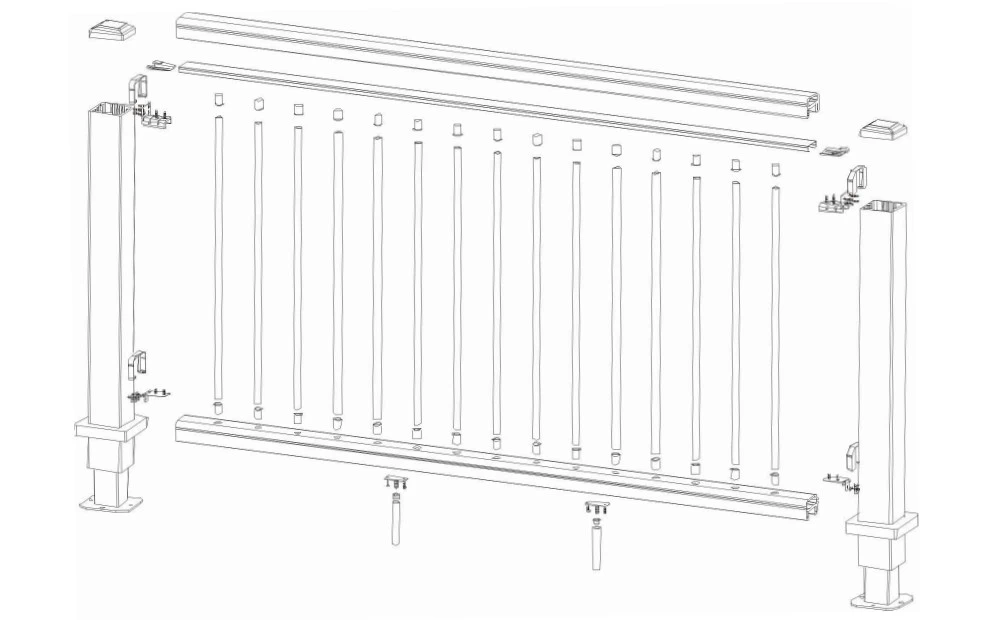

Accessories: Screws and Bolts, Anchors, Connectors and Clips, Post Caps, Cover Plates/Skirts, Drills and Drill Bits, Leveling Tools, Saw or Cutting Tools

Service life: 30+years,Dimensional Stability

Certificates: FSC,CE,ISO 90012008,SGS

Maintenance: Requires no painting,no glue,low maintenance

Packaging: wooden pallets, Carton,and corner protectors for safe delivery

Application: Parks, Recreational Areas, Boardwalks, Plank Roads, Bridges, Walkways, Gardens, Yards, Balconies, Patios, Swimming Pools, Public Facilities, Event Venues,and other places

WPC Ranch Railings (Composite Ranch Rail Fencing): Tailor-Made for Livestock Scenarios, A New Protective Choice Combining Durability and Safety

In the modern animal husbandry industry, ranch railings, as core facilities for dividing breeding areas, protecting livestock safety, and standardizing breeding order, their performance directly affects the operating efficiency and breeding safety of ranches. However, the emergence of WPC Ranch Railings (Composite Ranch Rail Fencing) perfectly solves the pain points of traditional materials .Traditional ranch railings mostly use metal, concrete, or pure wood materials. Metal railings are prone to corrosion and rust in the humid ranch environment, which not only have high maintenance costs but also may scratch livestock due to rusted parts; concrete railings are heavy and difficult to install, and cannot flexibly adjust area division; pure wood railings are easy to be gnawed by livestock and rot due to rain soaking, with a short service life. It combines the toughness of wood and the corrosion resistance of plastic, and at the same time has the characteristics of anti-gnawing, anti-impact, and easy maintenance. It can adapt to the complex environment of ranches with open air, humidity, and frequent livestock activities, providing stable, safe, and long-term protective solutions for various livestock scenarios such as dairy farms, beef cattle farms, and alpaca ranches, and becoming an ideal choice for the upgrading and transformation of modern ranches.

Major Advantages of the Product

✅ Super Corrosion and Moisture Resistance, Adapting to Complex Ranch Environments

The ranch environment is in an open-air state for a long time, and rain soaking and corrosion from livestock excrement are the main problems faced by railings. Composite Ranch Rail Fencing use a special process to composite wood fibers with polymer plastics to form a dense protective structure. Their water absorption rate is less than 2%, which is much lower than that of traditional wood (about 15%-20%). Even if they are in the humid ranch ground or rainy season environment for a long time, they will not rot, deform, or mildew. At the same time, the material itself does not contain organic nutrients, which can effectively resist the erosion of corrosive substances in livestock excrement, avoid the common rust phenomenon of metal railings, and there is no need to regularly apply anti-corrosion coatings or replace parts like traditional railings, which greatly reduces the maintenance cost and workload of the ranch. The service life can reach 15-20 years in the humid and highly corrosive ranch environment.

✅ Anti-Gnawing and Anti-Impact, Ensuring Dual Safety of Livestock and Railings

During the activities of livestock, gnawing on railings and colliding with fences are common behaviors. Traditional wood railings are easy to be damaged by gnawing, while metal railings may scratch the skin or teeth of livestock due to their hard material. The surface of it has undergone special wear-resistant treatment, with a hardness of more than Shore D grade 65, which can effectively resist the gnawing of cattle, sheep, and other livestock. Even if they are repeatedly rubbed or slightly gnawed by livestock, there will be no obvious damage or slagging, avoiding health problems caused by livestock eating wood chips or plastic fragments by mistake. At the same time, WPC material has good toughness and impact resistance, with a flexural strength of ≥25MPa. When livestock collide with the railings due to panic or activities, the railings can buffer the impact force through their own toughness, which will not break or be damaged, and can also reduce the impact injury to livestock, realizing the dual protection of livestock safety and railing structure safety.

✅ Anti-Slip and Anti-Tripping Design, Adapting to Livestock Activity Characteristics

Ranch railings not only need protection but also need to consider the convenience and safety of livestock's daily activities. They are fully adapted to the characteristics of livestock in structural design: the surface of the railings is treated with anti-slip texture to prevent livestock from slipping when touching the railings in rainy and snowy weather; the connection between the railing columns and crossbars adopts a circular arc transition design without sharp edges and corners to prevent livestock from being scratched or tripped when moving near the railings; at the same time, according to the size of different livestock, the railing spacing can be flexibly designed (for example, the spacing of railings in dairy farms is usually 12-15cm, and that in sheep farms is 8-10cm), which can not only prevent small livestock from drilling out of the fence but also not restrict the normal activities and feeding of large livestock, avoiding the problem of livestock being trapped or escaping due to improper spacing of traditional railings.

✅ Combination of Lightweight and High Strength, Facilitating Ranch Area Adjustment

Modern ranches often need to adjust the breeding areas according to the breeding scale and seasonal changes (such as group breeding, silage feed area division). Traditional concrete railings are heavy and cannot be moved, and metal railings are complex to disassemble and assemble, which is difficult to meet the needs of flexible adjustment. The density of it is only 1.1-1.3g/cm³, and the weight is about 1/5 of that of concrete railings of the same size and 1/3 of that of metal railings. 2-3 staff can easily carry and assemble them without large hoisting equipment. At the same time, the high-strength characteristics of the material ensure that the railings are not easy to be damaged during the process of disassembly and reorganization. The ranch can adjust the railing layout at any time according to the breeding plan to divide different functional areas such as calf areas, adult cattle areas, and isolation areas, which greatly improves the flexibility of ranch space utilization and adapts to the needs of large-scale and refined breeding in modern ranches.

✅ Environmental Protection and Odorlessness, Meeting Livestock Epidemic Prevention Standards

Livestock scenarios have extremely high requirements for the environmental protection and hygiene of facilities. The anti-corrosion coatings and metal platings used in traditional railings may release harmful substances, affecting livestock health and the breeding environment. No harmful chemicals such as formaldehyde and heavy metals are added during the production of Composite Ranch Rail Fencing. The formaldehyde emission of the finished product is ≤0.01mg/m³, which is far lower than the national E0-level environmental protection standard. Moreover, the material itself has no pungent odor and will not affect the sense of smell and health of livestock such as dairy cows and beef cattle, avoiding stress reactions of livestock (such as reduced milk production of dairy cows) caused by environmental odors. At the same time, WPC materials can be 100% recycled and reused, and will not cause environmental pollution after being discarded, which conforms to the concept of green breeding and sustainable development of modern ranches, and can also help ranches pass the inspection and certification of environmental protection and epidemic prevention departments.

✅ Modular Design, Reducing Installation and Maintenance Costs

It adopt a modular splicing structure, and accessories (such as buckles, connectors, and fixed bases) are all produced in a standardized manner. No complex welding or on-site processing is required during installation. Staff can complete the assembly using ordinary tools according to the instructions, and the installation efficiency is more than 30% higher than that of traditional railings, which is especially suitable for large-area fence construction in large-scale ranches. In terms of maintenance, the surface of the railings is smooth, and daily cleaning only requires rinsing with a high-pressure water gun to remove dirt such as livestock excrement and feed residues, without sanding and repainting like wood railings, or derusting and maintenance like metal railings. If local railings are damaged accidentally, only the corresponding modules need to be replaced without overall removal, further reducing the maintenance time and cost of the ranch.

Application of 8 Colors

Composite Ranch Rail Fencing provide 8 practical colors suitable for livestock scenarios, namely Dark Green, Light Gray, Earth Yellow, Dark Brown, Military Green, Off-White, Light Brown, and Navy Blue, which can be flexibly selected according to the functional division of the ranch, environmental coordination, and management needs. Dark Green and Military Green railings can integrate with the natural environment such as ranch grasslands and trees, reducing visual stimulation to livestock, and are suitable for outdoor open ranch fences; Earth Yellow and Light Brown railings are close to the color of soil, suitable for ranches in arid areas or matching with wooden livestock houses, creating a natural and coordinated breeding environment; Light Gray and Off-White railings have bright vision, suitable for areas that need to maintain cleanliness and hygiene such as dairy farms and calf areas, facilitating staff to timely find dirt or livestock excrement on the railing surface and improving cleaning efficiency; Dark Brown and Navy Blue railings have a calm color, which can be used in special functional areas such as ranch isolation areas and feed storage areas. The purpose of the area is clearly distinguished by color, assisting ranch management, and at the same time avoiding stress effects on livestock caused by overly bright colors.

OEM and ODM Services

To meet the personalized needs of different types of ranches, we provide professional OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services. In terms of OEM services, we can customize that meet the customer's brand identity and technical requirements according to the ranch scale, livestock species, and area planning drawings provided by the customer, including details such as railing height (conventional 1.2-1.8m, customizable high fences above 2m for large livestock breeding), number of crossbars, and spacing size. At the same time, we support printing the customer's ranch LOGO or safety warning signs on the railing surface to help customers build an exclusive brand image.In terms of ODM services, we have a professional R&D team for livestock scenarios, which can provide one-stop services from scheme design, sample production to mass production according to the customer's special needs (such as anti-freezing needs in alpine areas, windproof and reinforcement needs in windy areas, and anti-crowding needs in high-density breeding areas). For example, for alpine ranches, the material formula can be optimized to improve the low-temperature impact resistance of the railings (no breakage in -40℃ environment); for livestock that are easy to jump such as alpacas, a double-layer railing structure with anti-jumping crossbars can be designed; for mechanized breeding ranches, installation interfaces for automated feeding equipment and monitoring equipment can be reserved to realize seamless adaptation between railings and intelligent ranch equipment, fully meeting the personalized breeding needs of customers.

Relevant Qualification Certifications

Composite Ranch Rail Fencing strictly comply with the standards and environmental protection requirements of the livestock industry, and have passed a number of authoritative qualification certifications to ensure product quality and use safety. Firstly, the product has passed the "Performance Test of Livestock Farm Fence Facilities" of the National Agricultural Machinery Test and Appraisal General Station, and meets the "Technical Code for Livestock Farm Construction Engineering" (GB/T 51224-2017) in key indicators such as corrosion resistance, impact resistance, and anti-gnawing; secondly, it has passed the ISO 9001 Quality Management System Certification, with strict quality control in every link from raw material procurement (such as selecting high-quality poplar wood fibers for wood fibers and food-grade polyethylene for plastics) to production and processing, ensuring stable performance of each batch of products; at the same time, the product has also passed the ISO 14001 Environmental Management System Certification and China Environmental Labeling Product Certification (Ten-Ring Certification), proving that its environmental protection meets the requirements of national green agricultural development; in addition, for export needs, the product has passed the EU CE Certification and the US FDA Food Contact Grade Material Certification, ensuring that it can also meet strict quality and environmental protection standards in the international livestock market, allowing domestic and foreign ranch customers to use it with confidence.

Composite Ranch Rail Fencing Installation Steps

✅ On-Site Survey and Scheme Planning

Before installation, a field survey of the ranch installation area is required to clarify the boundary of the breeding area, ground flatness, soil type (such as whether it is soft soil or hardened ground), and livestock species (to determine the railing height and spacing). According to the survey results, an installation scheme is formulated, the installation positions of the railing columns are marked (conventional spacing 1.5-2m, which can be appropriately adjusted according to the railing height and impact resistance requirements), and the required WPC railing modules, connectors, expansion bolts, levels, electric drills and other tools and materials are prepared.

✅ Ground Pretreatment and Column Fixing

Pretreatment is carried out according to the ground type: if it is a hardened ground (such as cement ground), directly drill holes at the marked positions with an electric drill (the hole diameter and depth match the specifications of the expansion bolts), put the expansion bolts in, then sleeve the column base into the bolts and tighten and fix them, and use a level to ensure the column is vertical (verticality deviation ≤0.5°); if it is soft soil or muddy ground, it is necessary to first excavate a foundation pit with a depth of ≥30cm and a diameter of ≥20cm, fill it with concrete to fix the embedded parts, and after the concrete is cured for 72 hours, connect and fix the columns with the embedded parts to prevent the columns from tilting due to ground settlement.

✅ Crossbar and Module Splicing

After the columns are fixed, start installing the crossbars: connect the WPC crossbars with the columns through special buckles, and the buckles need to be embedded into the presets of the columns to ensure that the crossbars and columns are closely attached without loose gaps; according to the number of railing layers designed in the scheme (such as double-layer or three-layer crossbars), install the crossbars sequentially from bottom to top. After installing each layer, use a level to detect the levelness of the crossbars (horizontal deviation ≤1mm/m) to avoid the crossbars tilting and affecting the protective effect. If it is a railing module with vertical bars, directly splice the vertical bar modules with the crossbars through connectors to ensure that the spacing of the vertical bars is uniform and meets the design requirements.

✅ Detail Reinforcement and Protection Treatment

After all modules are spliced, reinforce the key parts: use self-tapping screws for secondary fixing at the connection points between columns and crossbars and the corners of the railings to enhance structural stability; if there are large livestock (such as beef cattle and horses) in the ranch, an anti-collision baffle can be installed at the bottom of the railings, with a gap of ≤5cm between the baffle and the ground to prevent the livestock from damaging the structure by hitting the bottom of the railings with their hooves; finally, spray a special wear-resistant protective agent on the surface of the railings to further improve the anti-gnawing and anti-ultraviolet performance of the railings and extend their service life.

✅ Acceptance and Commissioning

After the installation is completed, conduct a comprehensive acceptance: check whether all connectors are firm, and there is no obvious looseness when shaking the railings by hand; detect whether the railing height and spacing meet the design scheme and the livestock industry standards; simulate the livestock collision scenario (lightly hit the railings with a heavy object) to observe whether the railings are deformed or broken; clean up the tools and waste at the installation site to ensure that there are no sharp parts or debris left, avoiding potential safety hazards to livestock. If problems are found during the acceptance process (such as tilted crossbars and excessive spacing), adjust and repair them in a timely manner until they meet the use requirements.

Conclusion

With its core performance adapted to livestock scenarios, WPC Ranch Railings (Composite Ranch Rail Fencing) have broken the application limitations of traditional railings in the ranch environment and provided a comprehensive solution of "safety protection, long-term durability, flexible adaptation, and green environmental protection" for modern ranches. Whether it is used to divide breeding areas, protect livestock safety, or assist in the refined management of ranches, it can reduce the operating cost of the ranch and improve the breeding efficiency by virtue of its advantages of corrosion resistance, anti-gnawing, easy installation, and easy maintenance. We not only provide high-quality products that meet international standards but also can meet the personalized needs of different ranches through OEM/ODM services, providing professional support throughout the process from scheme design to installation and commissioning.

FAQ

1.Can this composite handle saltwater environments?

Yes! Its waterproof coating and anti-corrosion additives make it perfect for coastal areas.

2.Are custom colors available?

Absolutely. We match Pantone codes or create new hues to suit your design.

3.How does it perform in freezing temperatures?

Tested to resist frost damage and thaw cycles, ensuring year-round safety in alpine regions.

Contact Us

📧 Email: info@durable-fences.com

📞 Phone: +86 18066962697

💬 WhatsApp: +86 18066962697

🟢 WeChat: +86 18066962697

Choosing WPC Ranch Railings (Composite Ranch Rail Fencing) means choosing to build a solid, safe, and long-term protective barrier for the ranch, helping the ranch achieve large-scale, green, and intelligent development, and contributing to the high-quality upgrading of the livestock industry. We look forward to working with more ranch operators to jointly create a safe, efficient, and sustainable modern breeding environment.

Get a Quote for Your Fencing Project Today