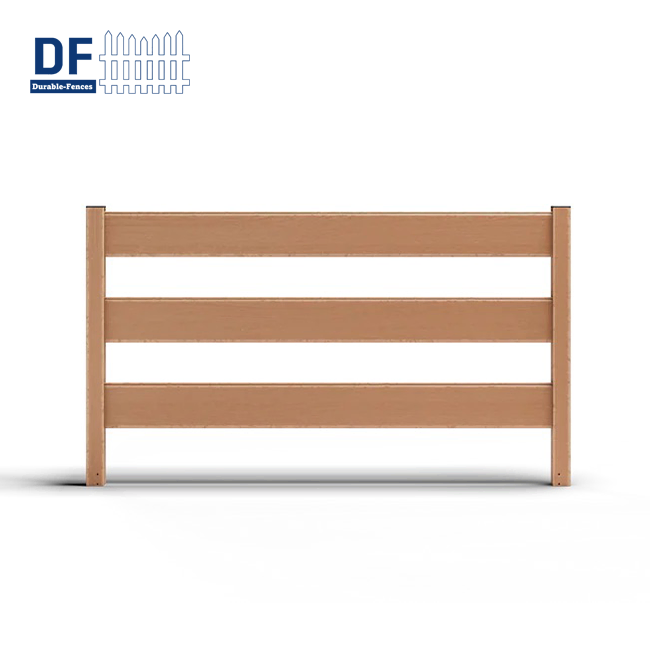

WPC Bridge Corridor Railings

Handrail: 60x40mm (2.36×1.57 inches), 80x40mm (3.15×1.57 inches), 90x45mm (3.54×1.77 inches), 100x50mm (3.94×1.97 inches), 105x50mm (4.13×1.97 inches), 160x80mm (6.30×3.15 inches), 200x80mm (7.87×3.15 inches), 200x100mm (7.87×3.94 inches),or customized

Beams: 35x35mm (1.38×1.38 inches), 40x40mm (1.57×1.57 inches), 60x40mm (2.36×1.57 inches), 60x60mm (2.36×2.36 inches), 73x73mm (2.87×2.87 inches), 80x80mm (3.15×3.15 inches),or customized

Length: customizable according to project needs

Material Composition: 60% recycled hardwood fibres+30% recycled polyethylene plastic(Grade A)+10% Additives (UV inhibitors, stabilizers, anti-slip treatments)

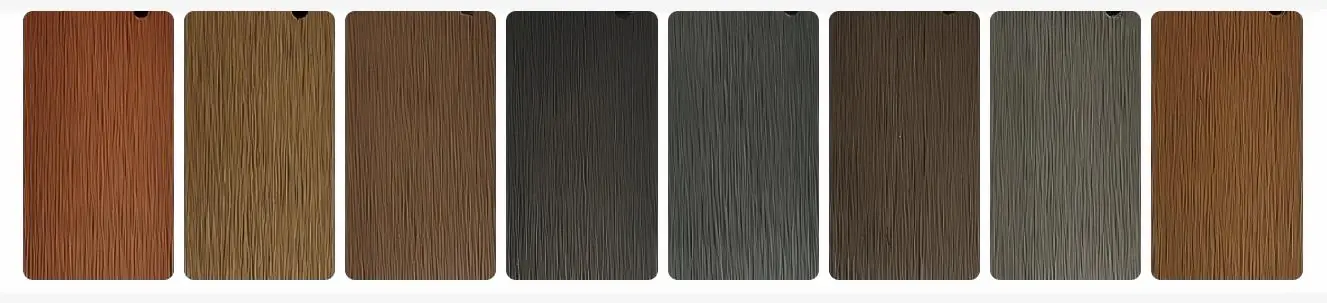

Surface: Normal,Brushed,Embossed,Co-extrusion,or customized

Accessories: Screws and Bolts, Anchors, Connectors and Clips, Post Caps, Cover Plates/Skirts, Drills and Drill Bits, Leveling Tools, Saw or Cutting Tools

Service life: 30+years,Dimensional Stability

Certificates: FSC,CE,ISO 90012008,SGS

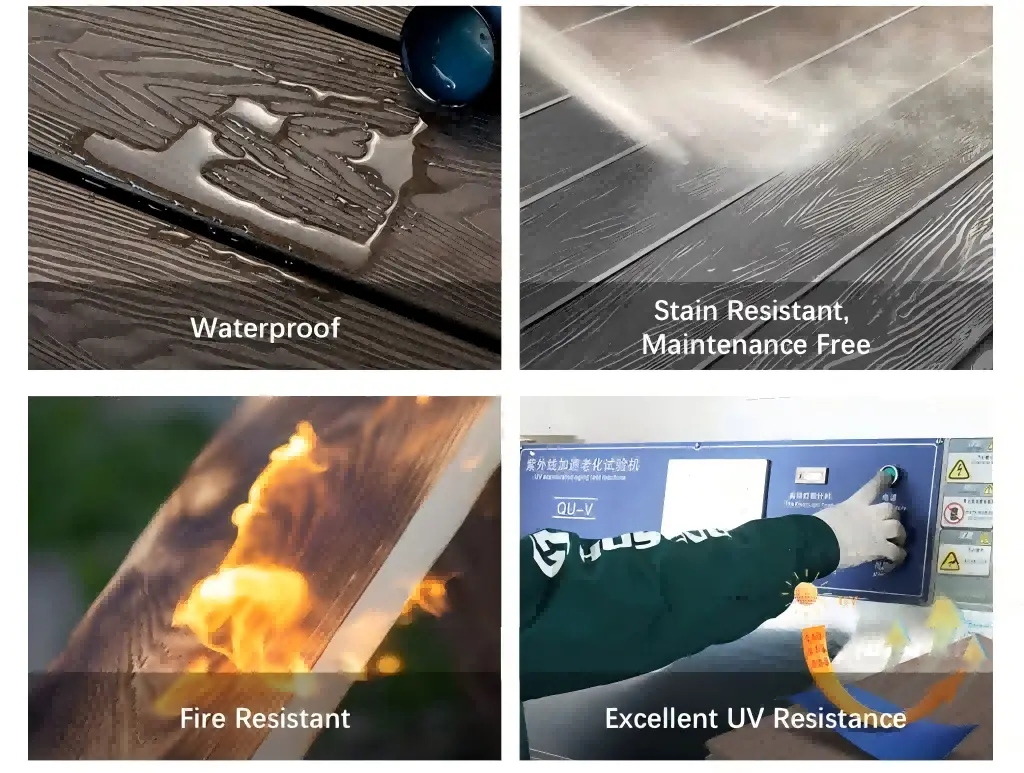

Maintenance: Requires no painting,no glue,low maintenance

Packaging: wooden pallets, Carton,and corner protectors for safe delivery

Application: Parks, Recreational Areas, Boardwalks, Plank Roads, Bridges, Walkways, Gardens, Yards, Balconies, Patios, Swimming Pools, Public Facilities, Event Venues,and other places

WPC Bridge Corridor Railings: Adapting to Bridge Corridor Scenarios, an Excellent Choice Combining Safety Protection and Landscape Integration

As an important channel connecting different building areas and spanning landscape water bodies or terrains, the bridge corridor is not only a transportation hub but also a key node for displaying the characteristic landscape of the space. The emergence of WPC Bridge Corridor Railings perfectly solves the pain points of traditional materials. As the core component of the bridge corridor, the bridge corridor railing not only needs to undertake the core function of pedestrian safety protection but also needs to coordinate with the overall design of the bridge corridor and the surrounding natural or humanistic landscape to enhance the aesthetics and experience of the space. Traditional bridge corridor railing materials have many adaptability problems: stone railings are heavy, have high requirements for the load-bearing capacity of the bridge corridor, and have a long installation cycle; metal railings are prone to rust when exposed to the humid environment of the bridge corridor for a long time, which not only affects safety but also requires frequent maintenance; wooden railings are easily affected by rain soaking and insect infestation, have a short service life, and are difficult to maintain the integrity of their appearance for a long time. It combines the natural texture of wood with the weather resistance and lightweight characteristics of plastic, and also has the advantages of high strength, corrosion resistance, easy installation, and strong landscape adaptability. It can easily meet the core needs of the bridge corridor, such as humid environment, large pedestrian flow, and landscape coordination, and has become an ideal choice for the construction and transformation of modern bridge corridors.

Major Advantages of the Product

✅ High Strength and Impact Resistance, Ensuring Pedestrian Safety in Bridge Corridors

As a high-frequency passage space, the bridge corridor requires railings to have sufficient strength and impact resistance to cope with situations such as pedestrian crowding and accidental collisions. WPC Bridge Corridor Railings adopt a composite process of wood fibers and polymer plastics, and add fiber-reinforced components. Their flexural strength is ≥28MPa and impact strength is ≥18kJ/m², which is far higher than the national safety standard for bridge corridor railings (flexural strength ≥20MPa). Even in the case of pedestrian crowding and collision during peak hours, or children leaning against the railings, or luggage carts scraping against them, the railings will not break or deform. They can effectively prevent pedestrians from accidentally falling and provide a solid guarantee for the traffic safety of the bridge corridor. At the same time, the surface of the railings is rounded, with no sharp edges and corners, avoiding pedestrians being scratched when passing through, and further improving the safety of use.

✅ Corrosion Resistance, Moisture Resistance and Salt Spray Resistance, Adapting to the Complex Environment of Bridge Corridors

Bridge corridors are often adjacent to water bodies (such as landscape lakes, rivers) or in open-air environments, with high air humidity. In addition, bridge corridors in some coastal areas also need to cope with salt spray erosion, which places high requirements on the corrosion resistance of the railings. They are optimized through a special formula, with a water absorption rate of less than 2%. Even if they are in a humid environment for a long time, they will not rot or mold. At the same time, the salt spray-resistant components added to the material can effectively resist the erosion of salt spray on the railings in coastal areas and avoid the common rust problem of metal railings.There is no need to regularly apply anti-corrosion coatings or replace parts like traditional railings. The service life can reach 15-20 years in the complex environment of bridge corridors, which greatly reduces the later maintenance cost and frequency and minimizes the impact on the normal traffic of the bridge corridor.

✅ Lightweight Design, Reducing the Load-Bearing Pressure of Bridge Corridors

The load-bearing capacity of the bridge corridor is one of the core considerations in design and construction. Traditional stone and metal railings are heavy, which will increase the load-bearing burden of the bridge corridor and limit the span and structural design of the bridge corridor. The density of it is only 1.1-1.3g/cm³, and the weight is about 1/4 of that of stone railings of the same size and 1/3 of that of metal railings. A single 1.5m-long railing weighs only 8-10kg, which can be easily carried and installed by 2-3 staff. The lightweight feature greatly reduces the load-bearing pressure of the bridge corridor, which is not only suitable for newly-built bridge corridors (optimizing the structural design of the bridge corridor and reducing construction costs) but also especially suitable for the transformation of old bridge corridors (no need for large-scale reinforcement of the load-bearing structure of the bridge corridor), expanding the application range of bridge corridor railings.

✅ Strong Landscape Adaptability, Integrating into the Overall Design of Bridge Corridors

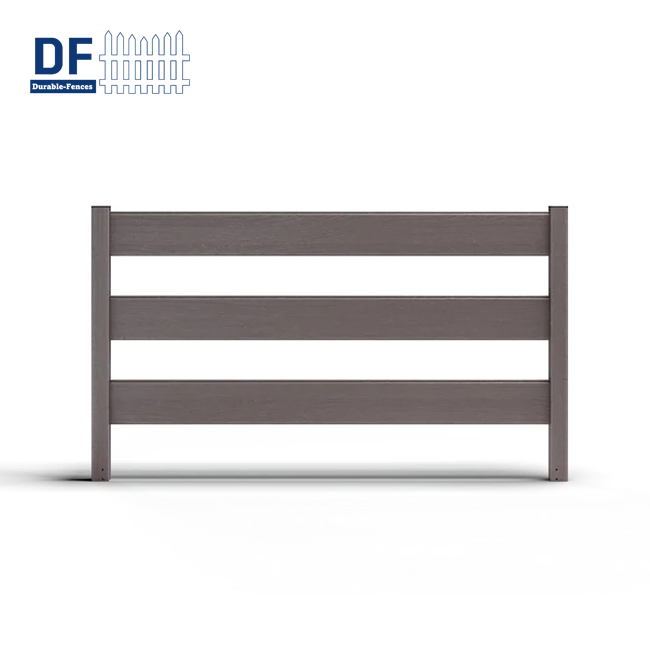

As a landscape node, the appearance design of the railings of the bridge corridor needs to coordinate with the style of the bridge corridor and the surrounding environment to avoid damaging the overall landscape beauty. They have extremely strong flexibility in appearance design: the surface can simulate the textures of various natural woods such as oak, pine, and walnut, presenting a natural and soft visual effect, which is suitable for bridge corridors of Chinese style, pastoral style, etc.; it can also be processed to create a simple texture such as solid color and frosted to meet the design needs of bridge corridors of modern minimalist style, industrial style, etc. In addition, the shape of the railings can be flexibly customized, such as simple vertical pole type, exquisite grid type, arc curve type, etc., and can also be matched with elements such as glass and metal decorative strips to echo the corridor columns, ground paving, surrounding green plants or water landscape of the bridge corridor, making the railings no longer an independent protective facility but an important part of the bridge corridor landscape, improving the aesthetics and coordination of the overall space.

✅ Anti-Slip, Wear-Resistant and Easy to Clean, Adapting to High-Frequency Use of Bridge Corridors

The bridge corridor has a large pedestrian flow, and the surface of the railings is easy to be stained with dust, rain stains, footprints, etc., and needs to be frequently touched, so the wear resistance and cleaning convenience of the railings are highly required. The surface of it has undergone anti-slip and wear-resistant treatment, with a surface hardness of more than Shore D grade 70. Even if it is touched and leaned against by pedestrians for a long time, there will be no obvious scratches or wear, maintaining the integrity of the appearance; at the same time, the surface is smooth and flat, with good stain resistance. Daily cleaning only needs to rinse with a high-pressure water gun or wipe with a damp cloth to remove surface dirt, without using special cleaning agents, and there is no need for sanding and maintenance like wooden railings or derusting treatment like metal railings. The simple maintenance method can ensure that the railings remain clean and beautiful for a long time, reducing the energy input in the daily management of the bridge corridor.

✅ Modular Quick-Installation Design, Shortening the Construction Period of Bridge Corridors

The construction or transformation of bridge corridors often needs to control the construction period and reduce the impact on the surrounding traffic and landscape. The installation process of traditional railings is complex (such as on-site cutting of stone railings and welding of metal railings), resulting in a long construction period. WPC Bridge Corridor Railings adopt a modular design, and components such as columns, crossbars, and vertical bars are all produced in a standardized manner, with complete accessories (such as buckles, connectors, fixed bases). No complex on-site processing is required during installation, and staff can complete the splicing and fixing with ordinary tools according to the instructions. The installation efficiency is more than 40% higher than that of traditional railings. Taking a 100m-long bridge corridor as an example, the installation of traditional railings takes 7-10 days, while the installation of it can be completed in only 3-5 days, which greatly shortens the construction period, reduces the impact on the traffic of the bridge corridor and the surrounding environment, and is especially suitable for public space bridge corridor projects with strict requirements on the construction period.

Application of 8 Colors

WPC Bridge Corridor Railings provide 8 colors suitable for the landscape of bridge corridors, namely Natural Wood Color, Light Walnut Color, Dark Brown, Light Gray, Dark Gray, Off-White, Cyan Gray, and Milk Tea Color, which can be flexibly selected according to the style of the bridge corridor and the surrounding environment. Natural Wood Color and Light Walnut Color railings have natural wood textures, which are suitable for Chinese-style and pastoral-style bridge corridors. Matched with wooden corridor columns and green plant landscapes, they create a natural and elegant atmosphere; Dark Brown railings have a calm color, which is suitable for European-style and neoclassical-style bridge corridors. Matched with stone floors and metal decorations, they show a solemn and elegant style; Light Gray and Dark Gray railings are simple and grand, suitable for modern minimalist and industrial-style bridge corridors. Combined with concrete and glass materials, they present a fashionable and neat visual effect; Off-White railings are fresh and bright, suitable for ins-style and light luxury-style bridge corridors. Matched with light-colored paving and soft decorations, they create a warm and comfortable space; Cyan Gray railings are close to the natural stone color, suitable for bridge corridors adjacent to water bodies. They echo the water surface and stone landscape, enhancing the natural integration of the space; Milk Tea Color railings are gentle and soft, suitable for leisure bridge corridors (such as park bridge corridors and community bridge corridors), improving the affinity and comfort of the space, and meeting the landscape adaptation needs of different bridge corridor scenarios.

OEM and ODM Services

To meet the personalized needs of different bridge corridor projects (such as municipal public bridge corridors, scenic spot landscape bridge corridors, commercial complex corridors, and community pedestrian bridge corridors), we provide professional OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services. In terms of OEM services, we can customize the products that meet the project requirements according to the bridge corridor design drawings, project brand logos, color parameters, and technical requirements provided by customers, including details such as the size of the railings (such as height 1.1-1.3m, adapting to different bridge corridor safety standards), shape (such as arc shape, straight line shape), texture, and color. At the same time, we support printing project LOGOs or safety warning signs (such as "No Climbing" and "Caution") on the surface of the railings to help customers create an exclusive bridge corridor image and meet the procurement needs of bulk bridge corridor projects.In terms of ODM services, we have a professional R&D and design team for bridge corridor scenarios. We can provide one-stop services from scheme design, sample production to mass production according to the customer's functional positioning of the bridge corridor (such as municipal traffic, scenic spot sightseeing, commercial leisure), surrounding environment (such as adjacent to water bodies, mountains, and building groups), and special needs (such as barrier-free access, night lighting, and integration of cultural elements). For example, for scenic spot landscape bridge corridors, we can design grid-type railings with local cultural patterns to integrate the cultural characteristics of the scenic spot; for bridge corridors adjacent to water bodies, we can design a double-layer railing structure with anti-fall nets to enhance safety; for bridge corridors frequently used at night, we can reserve LED light trough interfaces in the railings to realize the combination of lighting and protection, fully meeting the personalized and specialized bridge corridor railing needs of customers.

Relevant Qualification Certifications

WPC Bridge Corridor Railings strictly comply with national bridge corridor construction standards and environmental protection requirements, and have passed a number of authoritative qualification certifications to ensure product quality and use safety. Firstly, the product has passed the "Performance Test of Wood-Plastic Railings for Bridge Corridors" of the National Building Materials Testing Center, and meets the "Technical Code for Urban Pedestrian Overpasses and Underpasses" (CJJ 69-2017) and "Wood-Plastic Decorative Panels" (GB/T 24137-2009) in key indicators such as impact resistance, corrosion resistance, and weather resistance; secondly, it has passed the ISO 9001 Quality Management System Certification. From the procurement of raw materials (selecting high-quality recycled wood fibers and food-grade polyethylene plastics) to production and processing, and finished product inspection, there is a strict quality control process to ensure the stable and consistent performance of each batch of products; at the same time, the product has also passed the ISO 14001 Environmental Management System Certification and China Environmental Labeling Product Certification (Ten-Ring Certification), proving that its environmental performance meets the requirements of green building materials and will not pollute the surrounding environment of the bridge corridor; in addition, for export needs, the product has passed the EU CE Certification and the US ASTM Standard Certification, ensuring that it can also meet strict quality and environmental protection standards in international bridge corridor projects, allowing domestic and foreign customers to use it with confidence.

WPC Bridge Corridor Railings Installation Steps

✅ On-Site Survey and Scheme Confirmation

Before installation, a detailed survey of the bridge corridor site is required to clarify the length, width, ground material (such as stone, concrete, anti-corrosion wood), position of corridor columns, and surrounding environment (such as whether it is adjacent to water bodies and whether there are special landscape requirements) of the bridge corridor, and determine the installation position, height, shape, and fixing method (such as ground fixing, corridor column connection) of the railings. According to the survey results, combined with customer needs and the design style of the bridge corridor, a detailed installation scheme is formulated, installation drawings are drawn, and the details of the scheme are confirmed with the customer to ensure that the railings can perfectly fit the bridge corridor space after installation and meet the dual needs of safety protection and landscape coordination. At the same time, prepare the required WPC railing modules, connectors, expansion bolts, levels, electric drills, tape measures, and other tools and materials.

✅ Ground and Corridor Column Pretreatment

Pretreatment is carried out according to the ground and corridor column materials of the bridge corridor: if the ground is concrete or stone ground, first drill holes at the marked railing column installation positions with an electric drill (the hole diameter and depth need to match the specifications of the expansion bolts, with a depth of ≥15cm), and clean the dust and debris in the holes; if the ground is anti-corrosion wood ground, metal embedded parts need to be added at the installation positions to ensure that the columns are fixed firmly and avoid damage to the anti-corrosion wood; if the railings need to be connected to the corridor columns, drill holes at the marked positions on the corridor columns and install corridor column connectors to ensure that the connectors are closely attached to the corridor columns without loosening and do not damage the structural integrity of the corridor columns.

✅ Column Installation and Fixing

Place the WPC railing columns into the pre-treated installation positions, adjust the verticality of the columns (detected with a level, verticality deviation ≤0.5°), and ensure that multiple columns are arranged in a straight line or according to the designed arc (such as curved bridge corridors). For ground fixing, pass the expansion bolts through the reserved holes in the column base, screw them into the ground drill holes, and tighten the bolts to ensure that the columns are firm (the load-bearing capacity of a single column is ≥800N, meeting the needs of pedestrians leaning against); if connection to the corridor columns is required, fix the columns to the corridor column connectors with screws to ensure a tight connection. The conventional installation spacing of columns is 1.5-2m, which can be appropriately adjusted according to the railing height and impact resistance requirements to ensure structural stability.

✅ Crossbar and Vertical Bar Module Splicing

After the columns are installed, start installing the crossbars: connect the WPC crossbars to the columns through special buckles or connectors, and the buckles need to be embedded into the preset card slots of the columns to ensure that the crossbars and columns are closely attached without gaps or loosening. According to the design scheme, install the crossbars sequentially from bottom to top (usually double-layer or three-layer crossbars to enhance protection). After installing each crossbar, use a level to detect the levelness of the crossbar (horizontal deviation ≤1mm/m) to avoid the crossbar tilting and affecting the appearance and use. After the crossbars are installed, install the vertical bar modules, fix the vertical bar modules to the crossbars through connectors, adjust the spacing of the vertical bars (conventional spacing 10-12cm, in line with safety standards to prevent children from drilling out), and ensure that the spacing is uniform and consistent without deviation.

✅ Detail Processing and Acceptance

After all railing modules are installed, process the details: fill the gaps at the connection parts of the columns, crossbars, and vertical bars with special waterproof sealant to enhance waterproof performance and prevent rainwater from seeping into the connectors and causing damage; if the railings are equipped with decorative parts (such as column caps, connector decorative covers, and cultural pattern pendants), install the decorative parts in place to cover the connectors and optimize the overall appearance; if the railings reserve lighting interfaces, complete the installation of LED lights and line connection, and test the lighting effect. Finally, conduct a comprehensive acceptance: check whether all connection parts of the railings are firm, and there is no obvious loosening when shaking the railings by hand; detect whether the railing height, spacing, levelness, and verticality meet the design scheme and relevant standards; simulate the pedestrian leaning scenario (applying 800N force) to observe whether the railings are stable; clean up the tools, waste, and dust at the installation site to ensure that the bridge corridor environment is clean and tidy. If problems are found during the acceptance process (such as tilted crossbars, loose connectors), adjust and repair them in a timely manner until they meet the use requirements.

Conclusion

With its core advantages adapted to the bridge corridor scenario, WPC Bridge Corridor Railings provide a comprehensive solution of "safe and reliable, landscape coordination, long-term durability, and convenient installation" for the construction and transformation of bridge corridors. Whether it is the safety protection of municipal public bridge corridors, the cultural integration of scenic spot landscape bridge corridors, or the fashion and beauty of commercial complex corridors, it can enhance the use value and overall quality of the bridge corridor by virtue of its characteristics of high strength, corrosion resistance, and strong landscape adaptability. We not only provide high-quality products that meet high standards but also can meet the personalized needs of different bridge corridor projects through OEM/ODM services, providing professional support throughout the process from scheme design to installation and commissioning.

FAQ

1.How quickly can I get samples or a custom quote?

Samples ship in 3–5 business days. Custom quotes provided within 24 hours.

2.Is installation DIY-friendly?

Yes! Our modular design includes pre-drilled holes and step-by-step guides.

3.Do you offer regional compliance documentation?

We provide CE, UKCA, or ASTM certifications tailored to your location.

Contact Us

📧 Email: info@durable-fences.com

📞 Phone: +86 18066962697

💬 WhatsApp: +86 18066962697

🟢 WeChat: +86 18066962697

Choosing WPC Bridge Corridor Railings means choosing to add a safety barrier and a landscape highlight to the bridge corridor space, making the bridge corridor not only a traffic channel but also a high-quality space with both aesthetics and practicality. We look forward to working with more customers to jointly create high-quality bridge corridor projects and add more comfort and beauty to people's travel and leisure experience.

Get a Quote for Your Fencing Project Today