Anti Slip Composite Decking Boards

Length: 2m (7.22ft), 2.4m (7.87ft), 2.8m (9.19ft), 2.9m (9.51ft), 3m (9.84ft), 3.6m (11.81ft), 4m (13.12ft), 5.4m (17.72ft), customizable according to project needs.

Material Composition: 60% recycled hardwood fibres+30% recycled polyethylene plastic(Grade A)+10% Additives (UV inhibitors, stabilizers, anti-slip treatments)

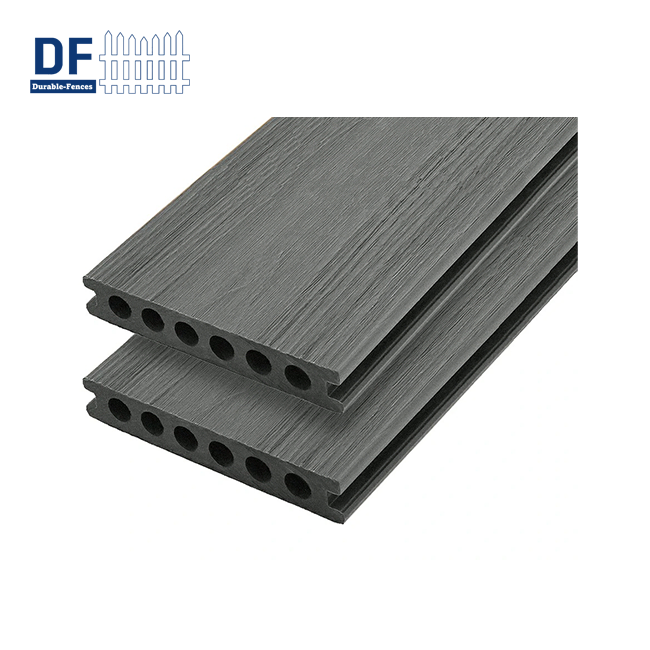

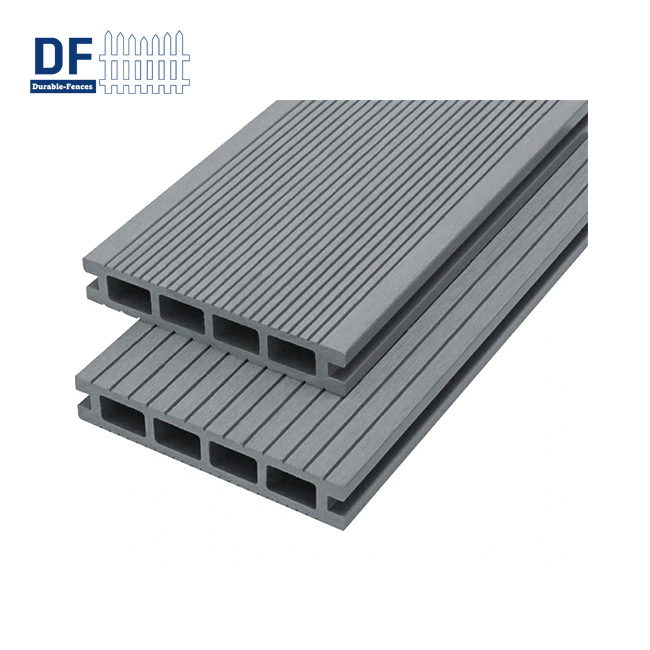

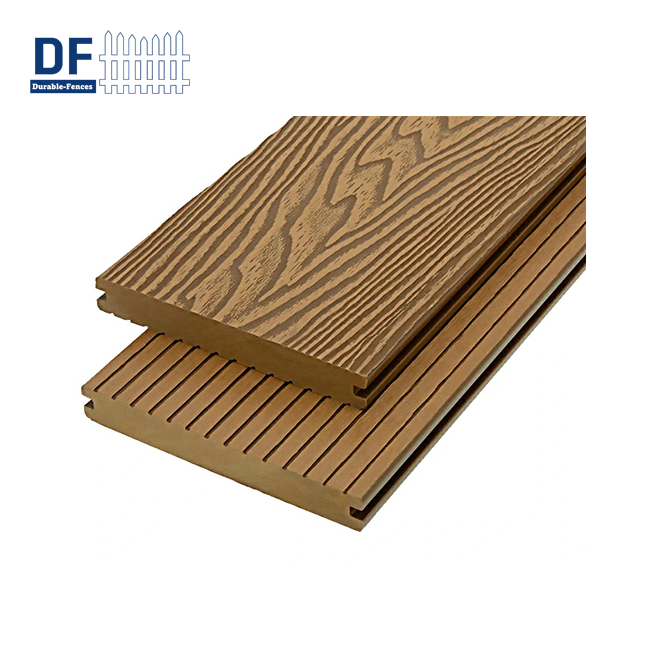

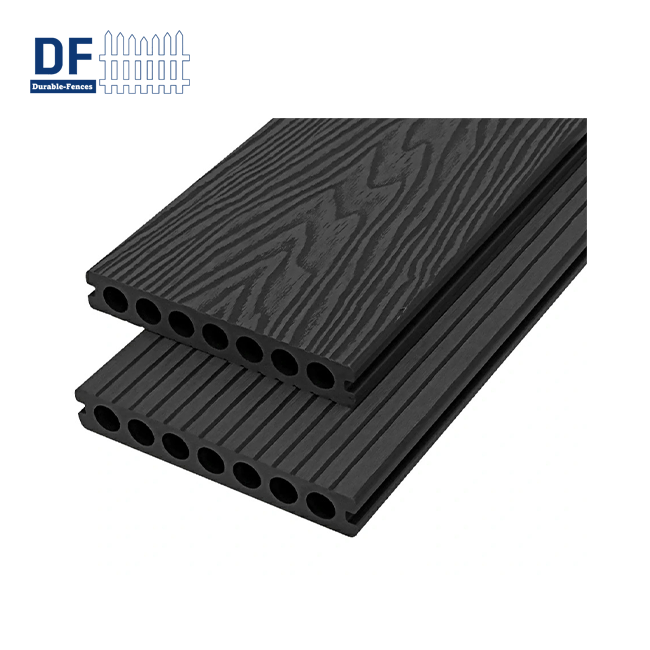

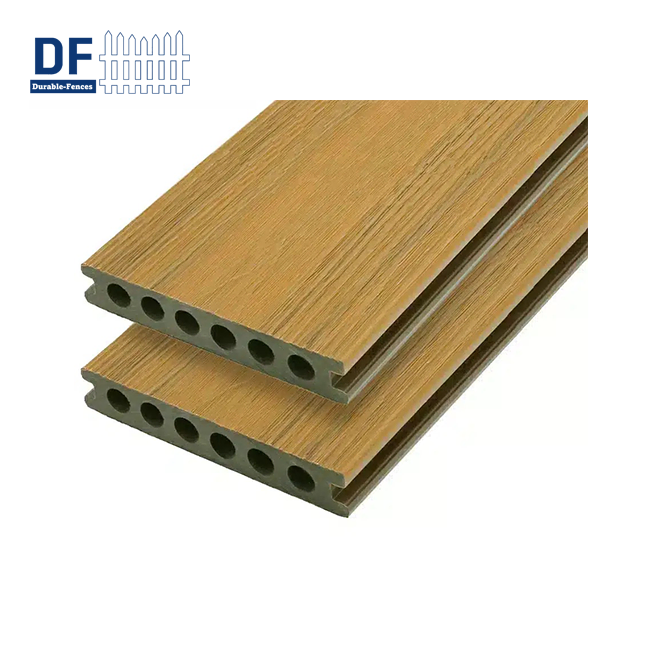

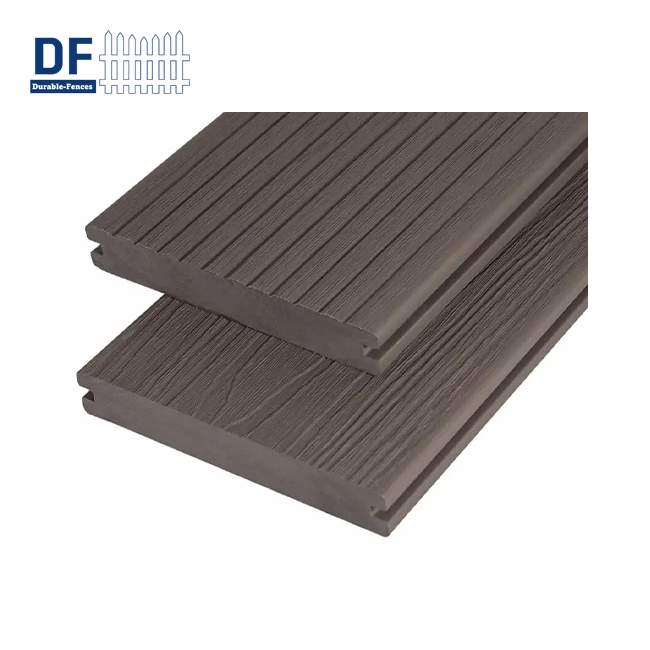

Profile: NormalSeries, 3D Embossed Series,Co-extrusion or customized

Surface treatment: grooving, embossing, sanding, and brushing

Accessories: joist,Edge Trim,end cover,cover,Clip with screw,expension screw,HXPA02 Plastic clip with screw,ss clip with screw,SS Starter clip with screw

Service life: 30+years,Dimensional Stability

Certificates: FSC,CE,ISO 90012008,SGS

Maintenance: Requires no painting,no glue,low maintenance

Packaging: wooden pallets, Carton,and corner protectors for safe delivery.

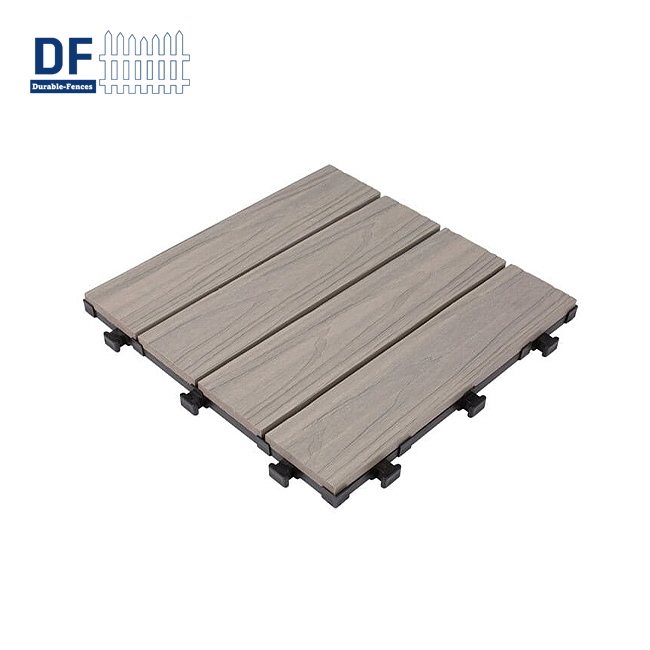

Application: gardenfloor, flower floor, patio flooring, or swimming pool floor, etc.

WPC Anti-Slip Flooring (Anti Slip Composite Decking Boards) : All-Scenario Safe Flooring Solution, Dual Advantages of Non-Slip Performance and Durability

In high-risk scenarios such as bathrooms, kitchens, swimming pool waterfront platforms, nursing home corridors, and shopping mall restrooms—where water exposure or dense foot traffic is frequent—"floor non-slip performance" is a core requirement for safety. The WPC Anti-Slip Flooring (Anti Slip Composite Decking Boards) breaks through with "triple non-slip technology", made of 60% natural pine fiber, 30% food-grade HDPE (High-Density Polyethylene), and 10% composite functional additives (including non-slip particles, anti-aging agents, and antibacterial agents) through a triple process of "non-slip texture embossing + non-slip coating spraying + non-slip substrate modification". Traditional non-slip materials struggle to adapt to high-risk scenarios long-term: ordinary non-slip tiles rely only on surface texture and fail when exposed to oil; non-slip stickers peel off easily; non-slip coatings wear out quickly; and metal non-slip plates feel cold and hard underfoot.It boasts all-scenario non-slip performance with a dry friction coefficient ≥0.8, wet friction coefficient ≥0.7, and oil-contaminated environment friction coefficient ≥0.6, while retaining the warm texture of wood. It is perfectly suitable for flooring scenarios requiring extreme safety protection, such as home bathrooms, commercial kitchens, elderly care institutions, and swimming pool surroundings.

Core Advantages: Safety Breakthroughs Brought by Triple Non-Slip Technology

Focusing on "safety needs in high-risk scenarios", Anti Slip Composite Decking Boards differs from the lightweight adaptability of general flooring, surface protection of co-extruded flooring, and isolation function of fences. It focuses on three core advantages: "all-scenario non-slip performance, long-term durability, and safety comfort":

✅ Triple Non-Slip Design · All-Scenario Safety Protection

- Surface Non-Slip Texture: Adopts "diamond-shaped concave-convex texture" (protrusion height 0.5mm, spacing 2mm) to increase friction on the contact surface, with a dry friction coefficient of 0.85—far exceeding the national safety standard of 0.6;

- Non-Slip Coating Spraying: The surface is covered with a nano-scale silica non-slip coating (thickness 5μm), which forms a hydrophilic film when exposed to water, enhancing the adhesion between water molecules and the floor. The wet friction coefficient remains 0.72, solving the pain point of "slipping when wet" with traditional flooring;

- Substrate Non-Slip Modification: 2% glass bead non-slip particles (particle size 50μm) are added to the substrate, evenly distributed within 3mm of the substrate surface. Even if the surface is worn, non-slip performance is maintained, with a friction coefficient of 0.63 in oil-contaminated environments—suitable for oily scenarios such as kitchens and restaurants.

✅ Long-Term Durable Structure · High-Risk Scenario Adaptation

The substrate density reaches 1.2g/cm³, with a single-point load-bearing capacity ≥600kg/m², capable of supporting heavy objects such as wheelchairs and cleaning carts—suitable for high-frequency use scenarios like elderly care institutions and shopping malls. After 10,000 wear tests (ASTM D4060 standard), the surface wear loss is ≤0.05g, and the non-slip performance attenuation rate is ≤5%, with a service life of up to 25 years. It has excellent chemical corrosion resistance, withstanding immersion in common stains such as detergent, disinfectant, and cooking oil (no discoloration or deformation for 24h), solving the problem of "easy corrosion and wear" with traditional non-slip materials. The water absorption rate is only 0.06%, with no mildew or expansion in long-term humid environments such as bathrooms and swimming pools, ensuring structural stability.

✅ Safe and Comfortable Experience · All-Crowd Adaptation

The surface texture is rounded (protrusion edge radius R0.3mm) to prevent foot bumps and injuries for the elderly and children. 1% antibacterial agent (silver ion component) is added to the substrate, with an antibacterial rate ≥99% (against Escherichia coli and Staphylococcus aureus)—suitable for bacteria-prone scenarios such as bathrooms and kitchens. It has a warm foot feel (thermal conductivity 0.15W/(m·K)), far lower than tiles (0.8W/(m·K)), with no cold feeling when walking barefoot in winter. It has excellent sound insulation performance (impact sound insulation ≤60dB), reducing floor impact noise in bathrooms and kitchens, and improving living comfort

✅ Convenient Installation and Maintenance · Reduced Usage Cos

Adopting a "snap-on splicing + waterproof rubber strip sealing" structure, no cement mortar paving is required. Two people can install 80-100㎡ per day, with an installation efficiency 4 times higher than traditional non-slip tiles. The splicing joint is equipped with a waterproof rubber strip (expansion rate ≥300%), which can effectively prevent water from seeping into the base layer through gaps—suitable for water-exposed scenarios. Daily cleaning only requires wiping with clean water or neutral detergent, and stains in non-slip textures can be cleaned with a soft brush, no professional maintenance is needed. A single damaged floor board can be replaced individually without overall demolition, with maintenance costs only 1/5 of traditional non-slip materials

Full-Dimension Customization Services: Exclusive Adaptation from High-Risk Scenarios to Details

Anti Slip Composite Decking Boards provides OEM, ODM, and personalized customization services. Aiming at "safety needs in high-risk scenarios", customization dimensions cover "non-slip performance, appearance design, and size adaptation" to meet the scenario-based needs of different customers:

✅ OEM Service · Standardized Bulk Production

Accepts OEM orders from domestic and foreign brands, with customizable core parameters: non-slip texture type , non-slip coating thickness, substrate density, and antibacterial agent content. Customized packaging (printed with brand LOGO and non-slip performance test report) is supported. Full-process tracking of "production-quality inspection-logistics" is provided, suitable for bulk procurement by building material distributors and elderly care institution service providers

✅ ODM Service · High-Risk Scenario-Exclusive Solutions

For customers without design solutions, one-stop ODM services are provided: a professional team first conducts "scenario risk research" (such as water exposure frequency, foot traffic, and pollutant type), then outputs 3D non-slip effect simulation diagrams, non-slip performance parameter tables, and cost budgets. Exclusive solutions can be designed (e.g., "high non-slip coating + dense texture" for swimming pool surroundings, "antibacterial non-slip + oil-resistant substrate" for commercial kitchens). For example, "salt spray-resistant non-slip flooring" is designed for cruise ships, and "antibacterial non-slip flooring" is designed for hospital ICUs.

Authoritative Certifications: Anti Slip Composite Decking Boards-Exclusive Safety Testing to Ensure Use in High-Risk Scenarios

Targeting the core demand of "non-slip safety in high-risk scenarios", Anti Slip Composite Decking Boards has passed domestic and foreign special certifications for non-slip building materials, covering key indicators such as non-slip performance, durability, and environmental safety, ensuring stable performance in water-exposed, oil-contaminated, and high-foot-traffic scenarios;

Each batch of products is accompanied by exclusive test reports covering core non-slip flooring indicators such as all-scenario non-slip coefficients, antibacterial rates, wear resistance, and chemical corrosion resistance; customers are supported to entrust third-party institutions such as Intertek and BV to conduct on-site sampling tests (e.g., wet non-slip tests for bathrooms, oil-contaminated non-slip tests for kitchens, wheelchair rolling tests for nursing homes); unqualified products are free to return ; "15-year warranty service" is provided (10-year warranty for non-slip coating, 15-year warranty for substrate layer); in case of quality problems such as non-slip performance attenuation (friction coefficient drop exceeding 10%), antibacterial failure, and structural deformation within the warranty period, free repair or replacement services are provided.

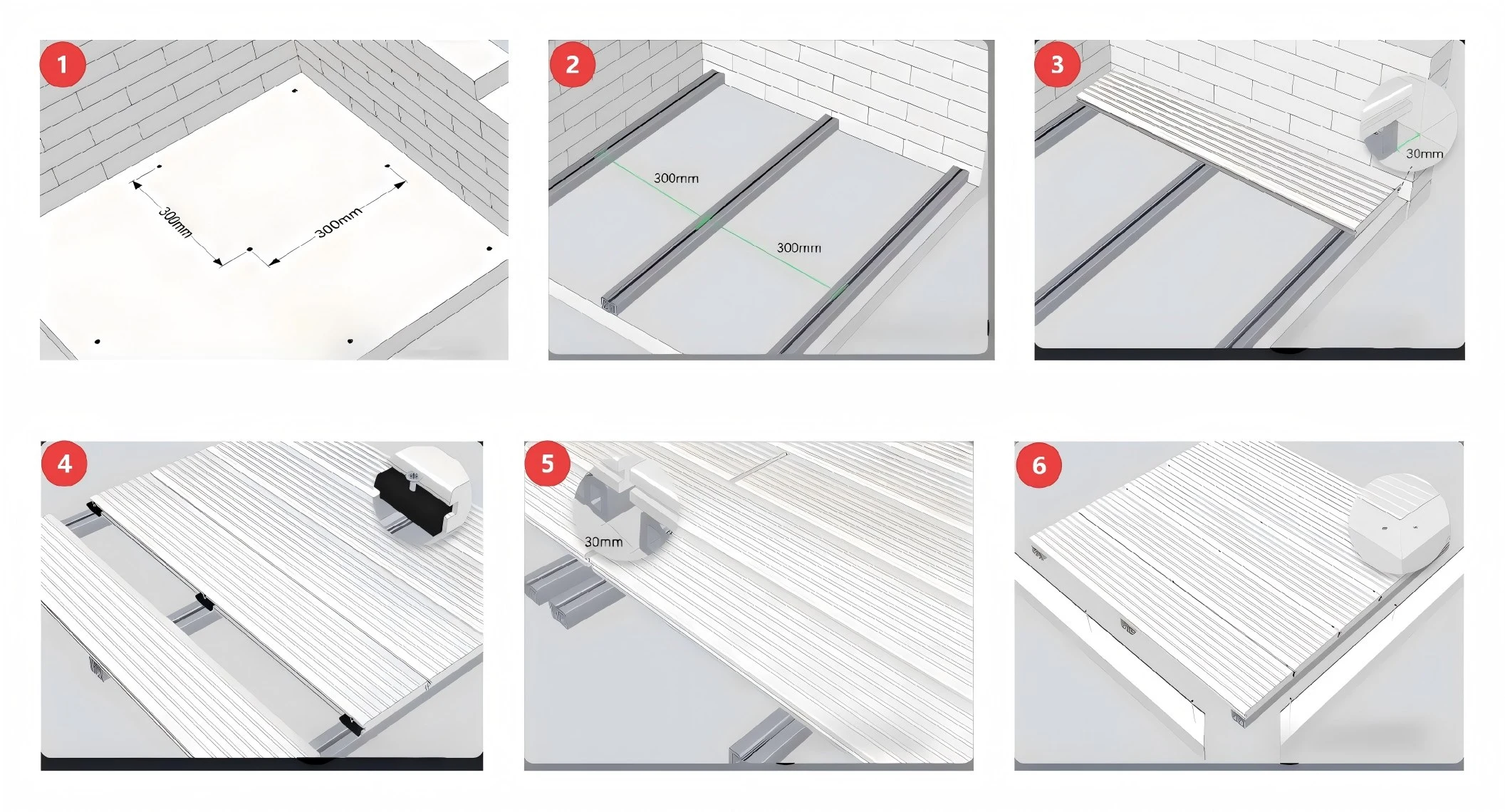

Standardized Installation Guide: Non-Slip Flooring-Exclusive Quick Installation Process, Safe Paving Completed in 6 Steps

Anti Slip Composite Decking Boards is designed to be waterproof and anti-slip in water-related scenarios. It uses a "waterproof pre-treatment + snap-on splicing + sealing reinforcement" design. It does not require a professional construction team, and basic renovation experience is sufficient. The steps are as follows:

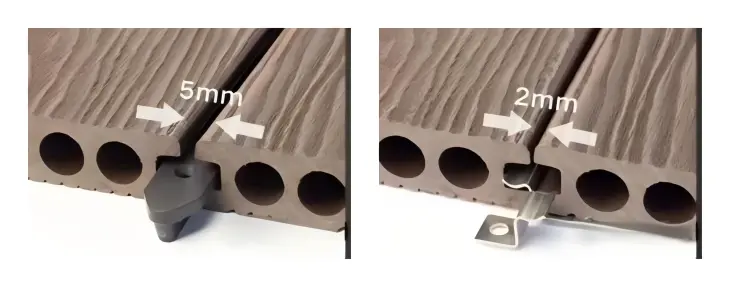

- Before fixing the joist, make sure the ground is clean and fat. Punching holes in the installation area with an impact drill. Knock the expansion pipe into the holes and make sure it is tight enough and will not be exposed.

- Take expansion pipes as the center line and lay joists on the line. Drill corresponding holes in the joist and fix the screws into the expansion pipes through the holes.

- Put the first decking board on the vertical way of a joist, and fasten the first decking board by screw(PS: do not use clips) outside the decking. The position and directions should be accurate and guaranteed to be the reference for the following decks.

- The first deck should be fastened directly by a screw instead of clips. Place the clip&screw in the right position and screw it. Insert the second decking board into the clips, then repeat this process.

- Two joists are needed for each deck at the juncture. In case of the deformation caused by temperature change, the joist should not be too tightly connected. We recommend a 3cm distance between two joists.

- Fasten the external sides of the last decking the same way as the first, and uninstall the end cover and decoration cover if necessary.

Installation Acceptance and Usage Maintenance Tips

✅ Acceptance Standards:

- Non-Slip Performance: Tested with a professional friction coefficient tester, dry ≥0.8, wet ≥0.7, oil-contaminated environment ≥0.6, meeting high-risk scenario safety standards;

- Waterproof Performance: 30min simulated water-exposure test, no water seepage, no stagnant water, smooth floor drain drainage (draining 5L water within 5min);

- Splicing Quality: Snaps tightly engaged, no looseness, no abnormal noise (no hollow sound when stepping), splicing gap ≤0.3mm;

- Flatness: Tested with a laser level, error ≤2mm within every 2m length, no protrusions, no depressions;

- Edge Trim Effect: Edge trim firmly fixed, sealant evenly applied, no bubbles, no cracks

✅ Usage Maintenance Tips:

- Daily Cleaning: Clean non-slip textures with clean water and a soft brush (avoid steel wool to prevent wearing the non-slip coating); for oily scenarios (e.g., kitchens), soak in neutral detergent for 5min before scrubbing; wipe with antibacterial disinfectant (chlorine concentration 500mg/L) once a month to maintain antibacterial performance;

- Regular Inspection: Check the sealant at splicing seams and edge trims every 3 months; if cracking or peeling occurs, repair with the same type of sealant in time; test non-slip performance with a friction coefficient tester every year; if attenuation exceeds 10%, apply a special non-slip maintenance agent (containing nano non-slip particles) to restore performance;

- Special Maintenance: For scenarios such as nursing homes and hospitals, avoid rapid wheelchair rolling over floor edges; install anti-collision strips on both sides of passages if needed; rinse swimming pool surrounding floors with fresh water once a week to avoid salt and chlorine residue corroding the non-slip coating;

- Problem Handling: Fill local scratches with color-matched non-slip repair agent (containing non-slip particles) and sand; if water seepage occurs, check the splicing seam sealant and reapply for reinforcement; contact the manufacturer for free replacement if large-area non-slip performance attenuation occurs within the warranty period.

Conclusion: A Safety Guardian for High-Risk Scenario Flooring

With "triple non-slip technology" as the core, WPC Anti-Slip Flooring (Anti Slip Composite Decking Boards) breaks the limitations of traditional non-slip materials—"single performance, poor durability, and many safety hazards". Through all-scenario non-slip coefficient compliance, long-term waterproof structure design, and all-crowd safety adaptation, it provides an "extremely safe, long-term durable" flooring solution for high-risk scenarios such as bathrooms, kitchens, elderly care institutions, and swimming pool surroundings,From 8 scenario-based color schemes balancing aesthetics and warning functions, to full-dimensional customization adapting to special scenario needs, and to 15-year warranty and free testing services ensuring long-term safety, it is not just a flooring material, but a "safety guardian" in high-risk scenarios.

FAQ

1.How do these boards handle heavy foot traffic in commercial settings?

The solid-core construction resists dents and scratches, maintaining aesthetics in airports, hotels, and retail spaces.

2.Are custom colors available?

Yes! Submit Pantone codes or physical samples for precise color matching.

3.What's the warranty coverage?

We offer a 15-year warranty against fading, staining, and structural defects.

Contact Us

📧 Email: info@durable-fences.com

📞 Phone: +86 18066962697

💬 WhatsApp: +86 18066962697

🟢 WeChat: +86 18066962697

Choosing WPC Anti-Slip Flooring (Anti Slip Composite Decking Boards) eliminates worries about slipping when wet, failure in oily environments, and frequent maintenance, allowing focus on scenario function experience. Every flooring space can balance safety, durability, and aesthetics, creating a worry-free environment for users

Get a Quote for Your Fencing Project Today