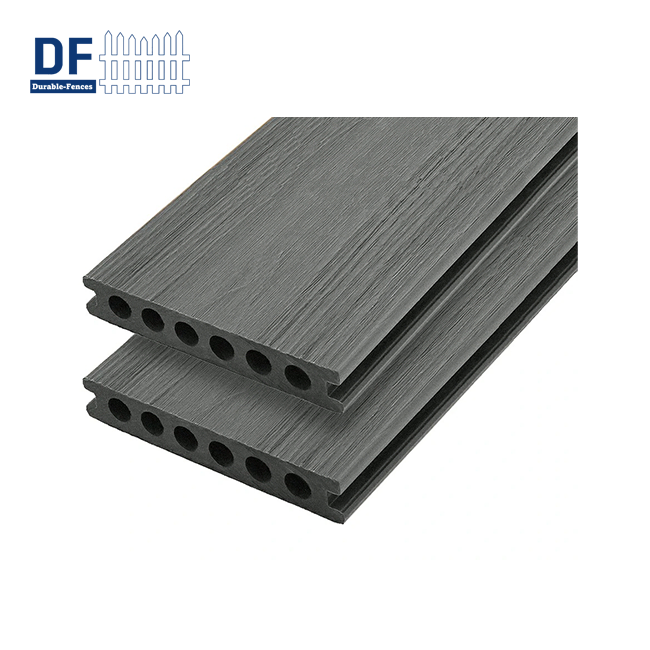

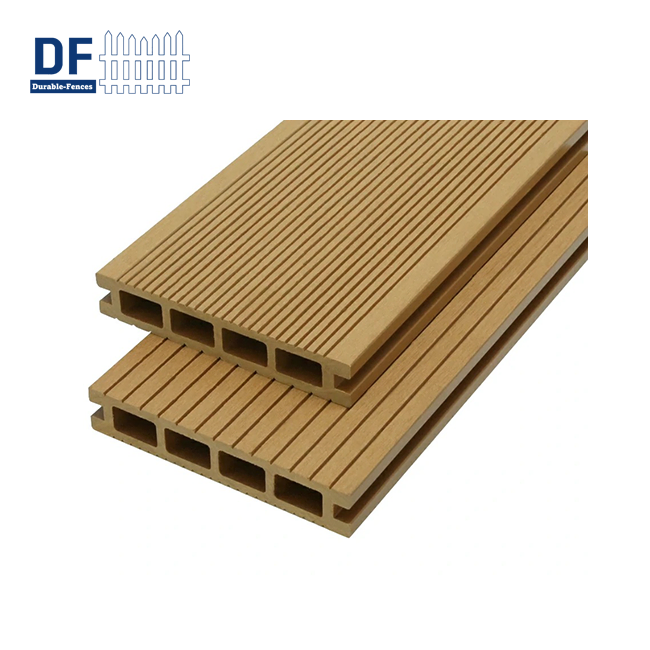

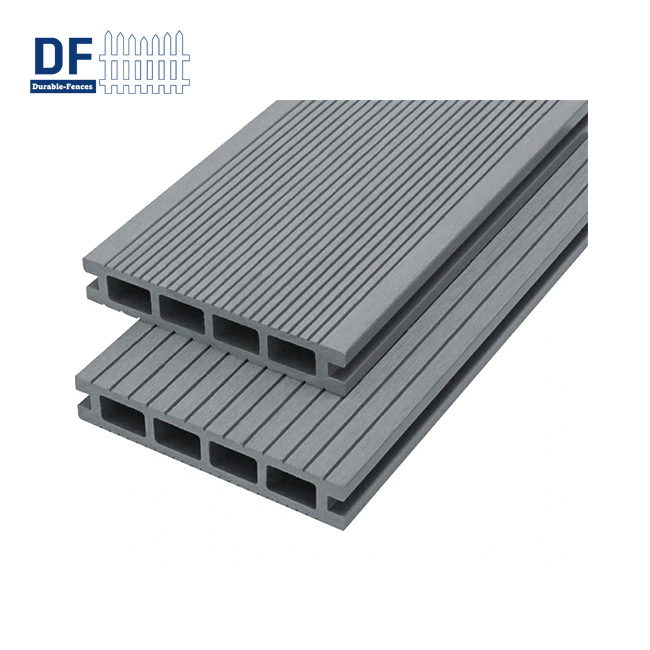

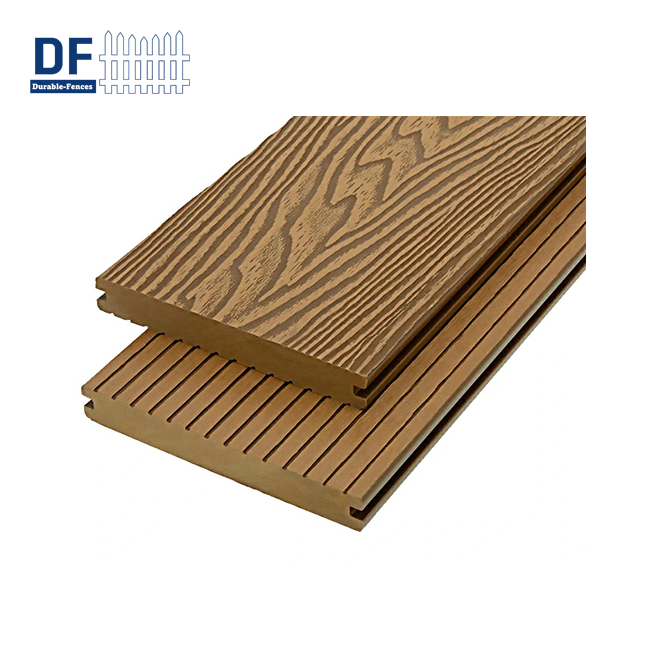

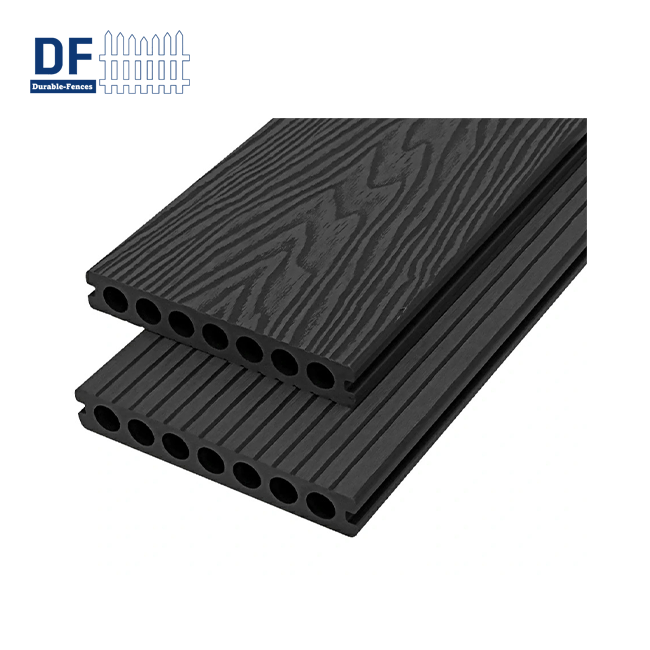

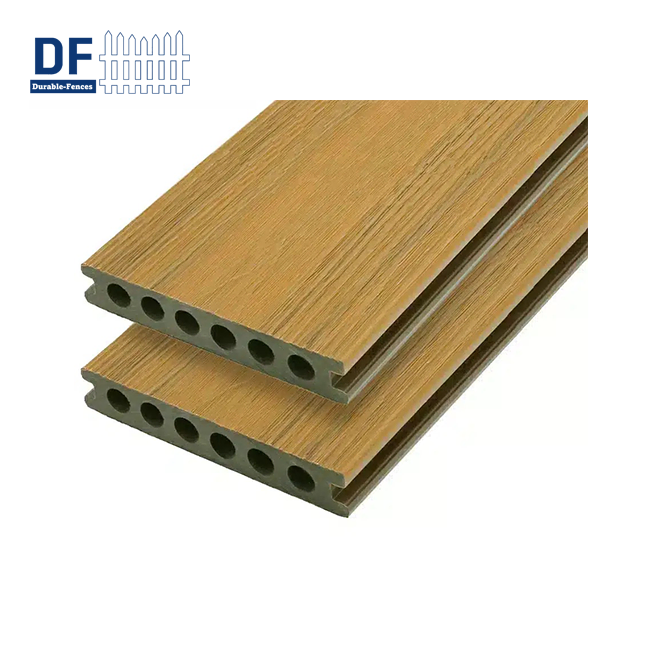

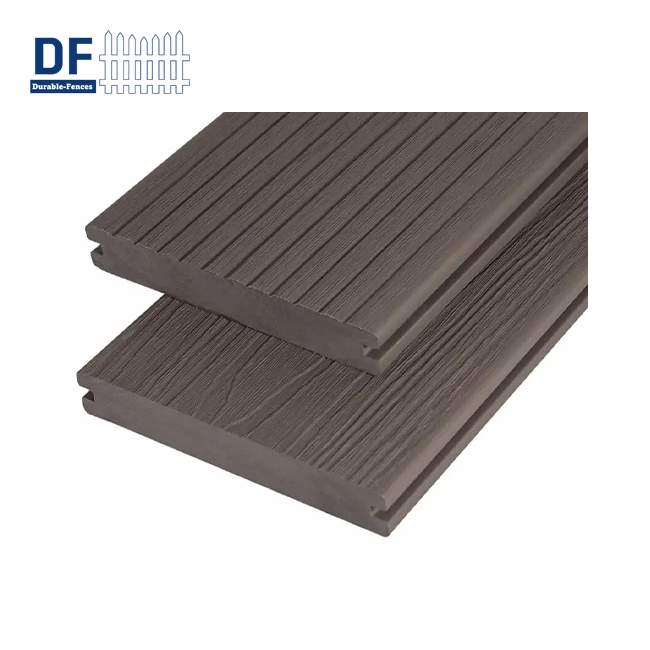

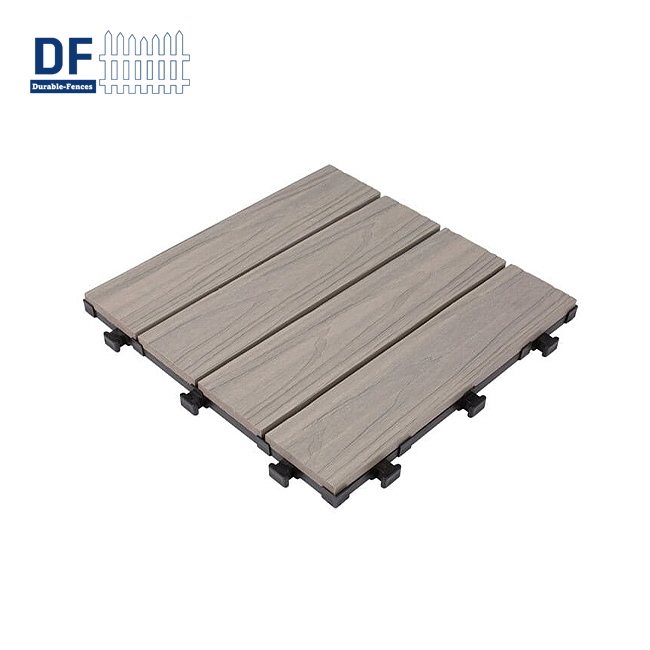

WPC Timber Decking

Width: 135/137/140/145/146/150/156/210/219/222mm or customized

Thickness: 12/20/21/23.3/23.5/24/25/30/38.5mm or customized

Material: 30%HDPE(Grade A Recycled HDPE)+ 60% Wood fiber component + 10% chemical additives

Recyclable: 100% Recyclable

Color: Cedar, charcoal, chocolate, coffee, grey, light gray, red wood, wood or customized

Profile: Solid /Square-Hollow /Round-Hollow

Accessories: Joist, wrap strip, screw, pedestal, clip

Service life: 25 years, Dimensional Stability

Certificates: FSC, CE, ISO 90012008, SGS

Maintenance: Requires no painting, no glue, low maintenance

Packaging: We use PE film and wood pallet & panel to package

Application: Gardens, Pools, Parks, Balconies, Patios, etc...

WPC General Flooring (WPC Timber Decking) : All-Scenario Lightweight Flooring Solution, Dual Advantages of Convenience and Durability

In scenarios such as home balconies, rental house renovation, temporary event venues, and small shops, flooring materials need to meet three core needs: "quick paving, low-cost maintenance, and multi-scenario adaptability". Traditional flooring materials are difficult to meet flexible use needs—either due to complex installation , heavy weight , or easy damage . The WPC General Flooring (WPC Timber Decking) breaks through with "lightweight structure + high adaptability", made of 60% wood fiber, 30% food-grade HDPE (High-Density Polyethylene), and 10% composite functional additives (including moisture-resistant agents, anti-deformation agents, and colorants) through one-time extrusion molding and surface matte treatment. It has the characteristics of "lightweight and portable (single piece weight ≤2kg/㎡), glue-free quick installation, and all-environment weather resistance". It not only retains the natural texture of wood, but also solves the pain points of traditional materials such as "difficult installation, expensive maintenance, and poor scenario adaptability", perfectly adapting to flooring scenarios that require flexible deployment such as balcony renovation, temporary exhibition halls, shop floors, and rental house renovation

Core Advantages: Dual Breakthrough in Lightweight Adaptability and Practical Durability

Focusing on "all-scenario flexible flooring needs", WPC Timber Decking differs from the high-strength protection of co-extruded flooring and the isolation function of fences, focusing on three core advantages: "lightweight quick installation, multi-scenario compatibility, and low-cost maintenance":

✅ Lightweight Structure · Convenient Deployment

Adopting "thin substrate + lightweight formula", the thickness of a single floor board is 8-12mm (8mm for temporary venues, 12mm for long-term use), and the weight per square meter is only 1.8-2.0kg, which is 90% lighter than traditional tiles (about 25kg/㎡) and 60% lighter than co-extruded flooring (about 5kg/㎡). It can be easily carried by a single person (10-15 pieces at a time) without professional hoisting equipment; the edge of the floor adopts "rounded thin edge design", and the overall thickness is uniform after splicing, which can be directly laid on the original floor (e.g., tiles, cement floor) without removing the old floor, greatly shortening the construction period (balcony renovation can be completed in only 2-3 hours).

✅ Glue-Free Quick Installation · Flexible Splicing

nnovatively adopting "self-adhesive locking structure", the lock is equipped with a self-adhesive strip (adhesion ≥3N/25mm, temperature resistance -20℃~60℃). When splicing, you only need to peel off the protective film, align the lock and press to fix, no additional glue or nailing is required. The installation time of a single piece is ≤1 minute, and 2 people can install 120-150㎡ per day; it supports "free cutting + staggered joint splicing", which can be cut with an ordinary utility knife (no woodworking saw required), adapting to irregular spaces (e.g., balcony curved corners, shop cash register surroundings); it can be disassembled and reinstalled at any time after splicing (the self-adhesive strip can be pasted repeatedly 3-5 times), meeting the needs of temporary venues (e.g., exhibitions, pop-up stores) for "short-term use and quick evacuation".

✅ All-Environment Weather Resistance · Low Maintenance Cost

The substrate water absorption rate is only 0.1%, with no mildew or expansion in humid balcony environments and rainy season shop floors; 1.5% anti-UV agent is added, with UV resistance level UV40+, and the color fading rate is ≤2% in 3 years under balcony exposure scenarios; the surface is matte treated (glossiness ≤15°), avoiding glare from strong light reflection, and the scratch resistance reaches 2H (pencil hardness test), which can resist daily furniture movement and sole friction; no regular waxing or painting is required, daily cleaning only needs to be wiped with clean water or neutral detergent, and the annual maintenance cost is less than 1 yuan/㎡, far lower than solid wood flooring (about 10 yuan/㎡).

✅ Multi-Scenario Compatibility · Safety and Environmental Protection

Adapting to "indoor + semi-outdoor" multi-scenarios: indoor can be used for rental house bedrooms and shop exhibition areas, semi-outdoor can be used for closed balconies and corridor aisles; the floor fire rating reaches Class B1 (GB 8624-2012), self-extinguishing when encountering open fire, no toxic gas release; formaldehyde emission ≤0.01mg/m³, far lower than the national standard E0 level (0.05mg/m³), suitable for closed spaces such as children's rooms and bedrooms; the edge rounded design (radius R2mm) avoids tripping of the elderly and children, and reduces collision damage during transportation.

Full-Dimension Customization Services: Exclusive Adaptation from Space Needs to Details

WPC Timber Decking provides OEM, ODM and personalized customization services. Aiming at the core demand of "flexible flooring deployment", the customization dimensions cover "structural design, appearance details, and size adaptation" to meet the scenario-based needs of different customers:

✅ Personalized Customization · 3 Core Dimensions

- Design Customization: Supports surface texture customization (e.g., fine-grained oak, coarse-grained walnut, geometric dark patterns), functional detail customization (e.g., edge anti-slip protrusions, surface antibacterial coating, sound-insulating adhesive backing), and pattern design customization (e.g., stripe splicing, square splicing, gradient splicing). For example, customizing "antibacterial surface + geometric dark pattern" flooring for children's rooms;

- Color Customization: In addition to 8 standard colors, accurate color mixing can be done according to the customer's color card (Pantone/RAL/NCS color codes), supporting two-color splicing (e.g., light grey + natural wood stripe splicing) with a minimum customization quantity of 30㎡ and color difference ΔE≤1.2, ensuring consistency with the space decoration color;

- Size Customization: The length can be adjusted from 600-1200mm (600mm for small spaces such as balcony corners, 1200mm to reduce splicing seams in large spaces such as shop exhibition halls), the width can be selected from 150-200mm (150mm for narrow areas such as corridors, 200mm to improve paving efficiency), and the thickness can be customized from 8-12mm (8mm for temporary venues such as exhibitions, 12mm for long-term use such as rental house bedrooms); it supports "zero-waste cutting" according to space dimensions, providing CAD cutting drawing services, marking accurate dimensions for irregular corners (such as balcony curved openings, shop cash register corners) to ensure the cut flooring fits perfectly with the space without secondary adjustments.

Authoritative Certifications: Lightweight Flooring-Exclusive Testing to Ensure Safety and Durability

Targeting the characteristics of "lightweight structure + multi-scenario use", WPC Timber Decking has passed domestic and foreign special certifications for flooring building materials, covering core indicators such as safety, environmental protection, and durability, ensuring stable performance while flexible deployment:

International Certifications: ISO 9001 Quality Management System Certification, ISO 14001 Environmental Management System Certification, EU CE Certification (EN 14041:2017 Standard for Outdoor Wood-Plastic Flooring certification for indoor and outdoor general models), American ASTM D6400-20 Standard for Compostable Plastics Compliance Certification (can be naturally degraded after disposal, environmentally friendly and pollution-free), SGS "Scratch Resistance" Certification (no scratches in 2H pencil hardness test), SGS "Fire Resistance" Certification (meeting BS 6387:1994 Class C fire standard, low smoke and low toxicity when exposed to fire).

Standardized Installation Guide: Lightweight Flooring-Exclusive Quick Installation Process, Paving Completed in 6 Steps

WPC Timber Decking is lightweight and glue-free, and adopts a "no foundation pretreatment + self-adhesive lock-joint splicing" design. No professional construction experience is required, and installation can be completed by individuals. The steps are as follows:

- Before fixing the joist, make sure the ground is clean and fat. Punching holes in the installation area with an impact drill. Knock the expansion pipe into the holes and make sure it is tight enough and will not be exposed.

- Take expansion pipes as the center line and lay joists on the line. Drill corresponding holes in the joist and fix the screws into the expansion pipes through the holes.

- Put the first decking board on the vertical way of a joist, and fasten the first decking board by screw(PS: do not use clips) outside the decking. The position and directions should be accurate and guaranteed to be the reference for the following decks.

- The first deck should be fastened directly by a screw instead of clips. Place the clip&screw in the right position and screw it. Insert the second decking board into the clips, then repeat this process.

- Two joists are needed for each deck at the juncture. In case of the deformation caused by temperature change, the joist should not be too tightly connected. We recommend a 3cm distance between two joists.

- Fasten the external sides of the last decking the same way as the first, and uninstall the end cover and decoration cover if necessary.

Conclusion: A Convenient Choice for All-Scenario Lightweight Flooring

With "lightweight structure + glue-free quick installation" as the core, WPC General Flooring (WPC Timber Decking) breaks the limitations of traditional flooring materials such as "complex installation, poor scenario adaptation, and high maintenance cost". It not only meets the "low-cost, rapid deployment" needs of home balcony renovation and rental house renovation, but also adapts to the "flexible disassembly and assembly, repeated use" characteristics of shop exhibitions and temporary exhibitions. At the same time, through 8 scenario-based color schemes and full-dimensional customization, it balances space aesthetics and functional needs.From the safety and environmental protection guaranteed by authoritative certifications, to the convenient experience brought by the standardized installation process, and to the long-term use advantage of low maintenance cost, Durable-fences provides a one-stop solution of "reliable performance and high cost-effectiveness" for various lightweight flooring scenarios.

FAQ

1. How does WPC handle heavy commercial use?

Our solid-core decking supports 500kg/m² loads, with anti-slip surfaces that stay scratch-free under constant foot traffic.

2. What certifications do you offer?

CE, FSC, ISO 9001, and B fire-rated compliance—ensuring smooth customs clearance globally.

3. Can I order samples?

Yes! Request color swatches or 30cm samples to verify quality before bulk orders.

Contact Us

📧 Email: info@durable-fences.com

📞 Phone: +86 18066962697

💬 WhatsApp: +86 18066962697

🟢 WeChat: +86 18066962697

Choosing WPC General Flooring (WPC Timber Decking) requires no professional construction or high budget, and can quickly create a clean, durable, and beautiful flooring space, allowing each scenario to flexibly adapt to usage needs and balance practicality and economy

Get a Quote for Your Fencing Project Today