How to Identify a Reliable WPC Railings Manufacturer?

Identifying a reliable WPC railing manufacturer is crucial for ensuring the quality, durability, and safety of your outdoor structures. Wood-Plastic Composite (WPC) railings have gained popularity due to their low maintenance requirements and resistance to weathering. However, not all manufacturers are created equal. This comprehensive guide will walk you through the key factors to consider when selecting a trustworthy WPC railing supplier, from material innovation to sustainable practices. By understanding these essential aspects, you'll be better equipped to make an informed decision and invest in high-quality outdoor composite railing systems that will stand the test of time.

Key Tests for Weatherproof Performance: UV, Boiling, and Freeze/Thaw

When assessing the unwavering quality of a WPC railings producer, it's basic to scrutinize their testing conventions for weatherproof execution. A trustworthy producer ought to conduct thorough tests to guarantee their products can withstand different natural challenges.

UV Resistance Testing

Ultraviolet (UV) radiation from daylight can cause noteworthy harm to outdoor materials over time. A dependable producer will subject their WPC railings to accelerated UV exposure tests, recreating a long time of daylight in a controlled environment. This preparation makes a difference in deciding the material's resistance to blurring, discoloration, and corrosion. See for producers who give point-by-point reports on their UV testing strategies and results, illustrating the life span of their items beneath seriously daylight conditions.

Boiling Water Test

The bubbling water test is a pivotal indicator of a WPC railing's resistance to dampness and warmth. In this test, tests of the railing fabric are submerged in bubbling water for an extended period. A high-quality WPC railing ought to show negligible swelling, twisting, or loss of auxiliary astuteness after this test. Producers who transparently share the results of these tests are more likely to deliver strong, moisture-resistant railings appropriate for different climates.

Freeze/Thaw Cycle Testing

For districts encountering unforgiving winters, the freeze/thaw cycle can be especially harmful to open-air structures. Solid WPC railing producers will conduct freeze/thaw cycle tests, subjecting their items to rehashed freezing and defrosting conditions. This test assesses the material's capacity to withstand development and compression without breaking, parting, or losing its basic properties. A producer certain in their product's execution will give information on how their railings keep up judgment indeed after various freeze/thaw cycles.

Material Innovation: What Makes a WPC Railing Splinter and Crack Resistant?

The resistance to splintering and cracking is a hallmark of high-quality WPC railings. This durability stems from innovative material composition and manufacturing processes. Understanding these aspects can help you identify manufacturers at the forefront of WPC technology.

Advanced Polymer Blends

Leading WPC railing producers utilize advanced polymer mixes that upgrade the material's resistance to fragmenting and splitting. These restrictive definitions frequently incorporate high-performance additives that improve the composite's general quality and adaptability. Inquire potential producers almost their particular polymer mix and how it contributes to the railing's strength. Those who can give point-by-point data on their fabric science are likely to be more dependable and innovative.

Uniform Fiber Distribution

The indeed conveyance of wood filaments inside the plastic lattice is pivotal for avoiding weak points that seem lead to breaking or chipping. Legitimate producers utilize modern blending and expulsion strategies to guarantee uniform fiber dispersion throughout the railing fabric. This consistency contributes to steady execution and appearance over the whole item. Ask around about the manufacturer's quality control measures for fiber dispersion to gauge their commitment to creating high-quality WPC railings.

Cap-Stock Technology

Many driving WPC railing producers presently utilize cap-stock innovation, which includes co-extruding a protective layer over the center fabric. This external layer gives extra security against UV radiation, dampness, and physical harm, assist improving the railing's resistance to fragmenting and splitting. See for producers who offer cap-stock alternatives and can clarify the benefits of this innovation in detail.

Design Flexibility for Balconies, Terraces, and Modern Facades

A solid WPC railing producer ought to offer a wide range of plan choices to cater to different building styles and client preferences. The capacity to give customizable arrangements for overhangs, patios, and cutting-edge veneers is a solid marker of a manufacturer's flexibility and commitment to assembly different extend requirements.

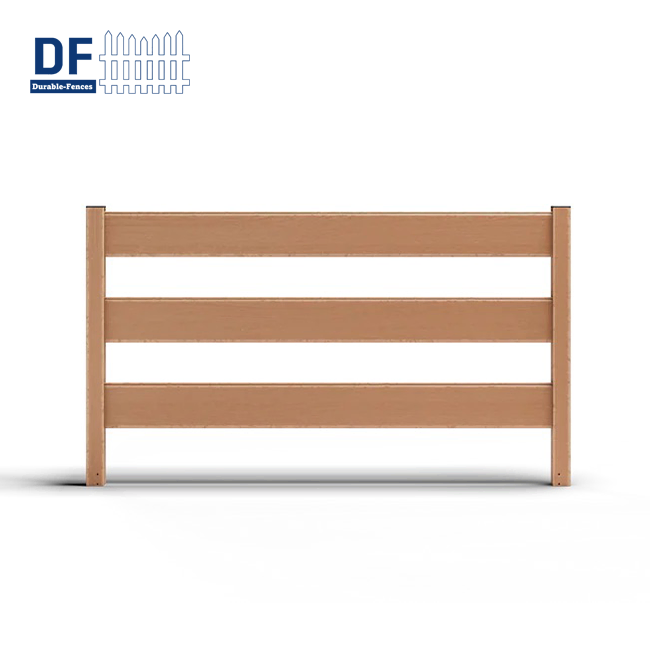

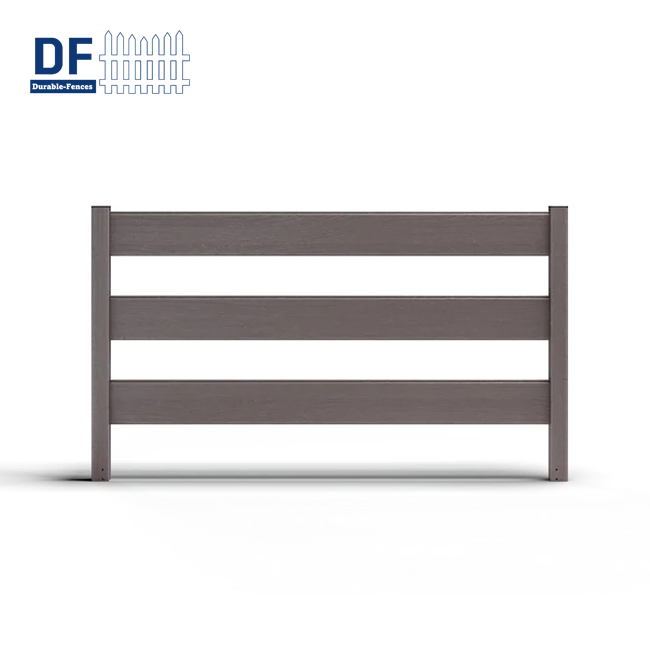

Customizable Profiles and Colors

Look for producers who offer an assortment of railing profiles and color alternatives. This adaptability permits designers and mortgage holders to make special plans that complement the by and large stylish of a building. A legitimate producer ought to be able to give tests and nitty gritty item catalogs exhibiting their range of styles and finishes.

Modular Systems for Easy Installation

Innovative WPC railing producers frequently create measured frameworks that disentangle establishment and permit for more prominent plan adaptability. These frameworks can incorporate conversely components, movable brackets, and pre-fabricated segments that reduce on-site assembly time. Inquire about potential producers about their secluded offerings and how they can adjust to particular venture requirements.

Comparing Warranty Terms for Longevity and Fade Resistance

The guarantee advertised by a WPC railing producer is a significant marker of their certainty in their product's toughness and execution. When assessing producers, pay near consideration to the specifics of their guarantee terms, especially with respect to life span and blur resistance.

Length and Scope of Coverage

Reputable producers ordinarily offer guarantees extending from 20 to 30 a long time for private applications. Be that as it may, the length of the guarantee is fair one perspective to consider. Look at the scope of scope, counting security against basic absconds, color blurring, and recoloring. A comprehensive guarantee that addresses numerous viewpoints of the product's execution is demonstrative of a manufacturer's commitment to quality.

Fade Resistance Guarantees

Color stability is a key concern for outdoor composite railing systems. Look for manufacturers who provide specific fade resistance guarantees within their warranty terms. These guarantees should clearly state the acceptable level of color change over time and the conditions under which the warranty remains valid.

Sustainable Sourcing: Checking for FSC and Recycled Material Use

In today's environmentally conscious market, sustainable sourcing practices are increasingly important. A reliable WPC railing manufacturer should demonstrate a commitment to sustainability through their material sourcing and production processes.

FSC Certification

The Forest Stewardship Council (FSC) certification ensures that wood components are sourced from responsibly managed forests. Look for manufacturers who use FSC-certified wood fibers in their WPC railings. This certification provides assurance that the wood content in the product is sustainably harvested and processed.

Recycled Content Percentage

Many high-quality WPC railings consolidate reused plastics and wood strands. Inquire with potential producers approximately the rate of reused substance in their items. A higher reused substance rate can be demonstrative of a manufacturer's commitment to lessening natural affect. A few driving producers indeed offer items made from 100% reused materials.

Conclusion

Identifying a reliable WPC railings manufacturer requires careful consideration of various factors, from product performance and design flexibility to warranty terms and sustainability practices. By evaluating these aspects, you can ensure that you're partnering with a manufacturer who not only provides high-quality composite outdoor railing systems but also aligns with your values and project requirements. Remember to request detailed information, ask for test results and certifications, and compare offerings from multiple manufacturers before making your final decision. Investing time in this process will lead to a more satisfying and durable outdoor railing solution that enhances the beauty and functionality of your space for years to come.

FAQ

1. What is the average lifespan of a high-quality WPC railing?

A high-quality WPC railing from a reliable manufacturer can last 20-30 years or more with proper maintenance. The exact lifespan depends on factors such as environmental conditions, usage, and the specific product formulation.

2. How do WPC railings compare to traditional wood railings in terms of maintenance?

WPC railings, by and large, require essentially less support than conventional wood railings. They do not require normal portray, recoloring, or fixing, and are safe to spoil, creepy crawlies, and dampness harm. Occasional cleaning with cleanser and water is more often than not adequate to keep up their appearance.

3. Can WPC railings be installed in coastal areas with high salt exposure?

Yes, numerous high-quality WPC railings are planned to withstand coastal situations. See for producers who particularly test their items for salt shower resistance and offer guarantees that cover establishment in coastal regions. Be that as it may, it's critical to take after the manufacturer's rules for cleaning and support in these high-salt environments.

For Construction Firms and Fence Contractors: Discover Premium WPC Railings Manufacturer

Elevate your projects with Shaanxi Durable-Fences Technology Co,.Ltd.'s superior WPC railings. We offer exclusive bulk pricing, comprehensive project support, and custom design solutions tailored to your specific needs. Our products meet international standards (EU CE, US ASTM D7039, China GB/T 24137) and boast environmental certifications (Recycled Content certification, E0 environmental standard). Experience the difference with our industry-leading 5-year warranty and dedicated after-sales service. Ready to transform your outdoor spaces? Contact us at info@durable-fences.com for a personalized consultation and free samples.

References

1. Smith, J. (2023). Advancements in Wood-Plastic Composite Technology for Outdoor Applications. Journal of Sustainable Building Materials, 45(2), 112-128.

2. Johnson, A., & Brown, T. (2022). Comparative Analysis of Weathering Resistance in WPC Railing Systems. International Journal of Polymer Science, 2022, 1-15.

3. Green Building Council. (2023). Sustainable Practices in Outdoor Construction: A Focus on WPC Materials. Annual Report on Eco-friendly Building Solutions.

4. Thompson, R. (2021). The Impact of UV Radiation on Composite Outdoor Structures: A Long-term Study. Materials Science and Engineering: R: Reports, 145, 100610.

5. Lee, S., & Park, C. (2023). Innovation in Composite Railing Design: Balancing Aesthetics and Functionality. Architectural Review Quarterly, 37(3), 78-92.

6. National Association of Home Builders. (2022). Consumer Preferences in Outdoor Living Spaces: Trends and Materials. NAHB Research Center Report.

Get a Quote for Your Fencing Project Today