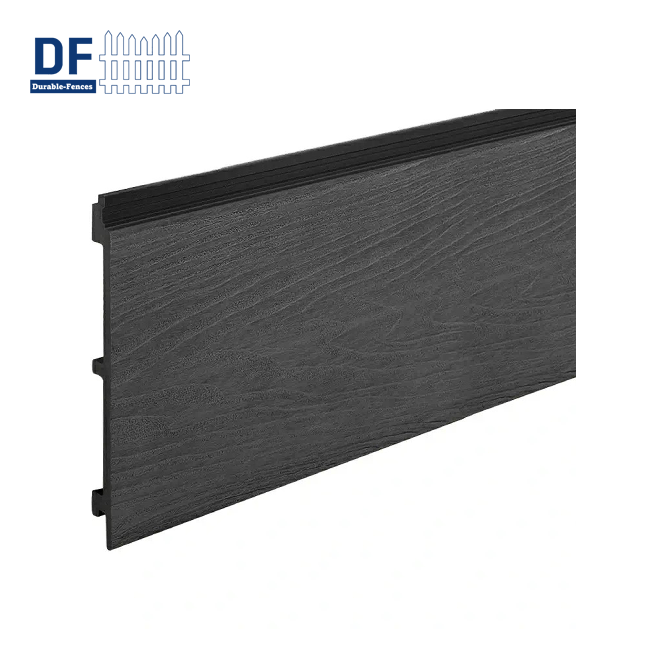

Horizontal Cladding Panels

Length:2.2m,2.9m,3.6m, 5m or customized

Material: 30%HDPE(Grade A Recycled HDPE)+ 60% Wood fiber component + 10% chemical additives

Thickness:17mm,19mm,21mm,26mm,31mm etc.

Recyclable: 100% Recyclable

Profile: Solid/Square Hollow/Great Wall Panel

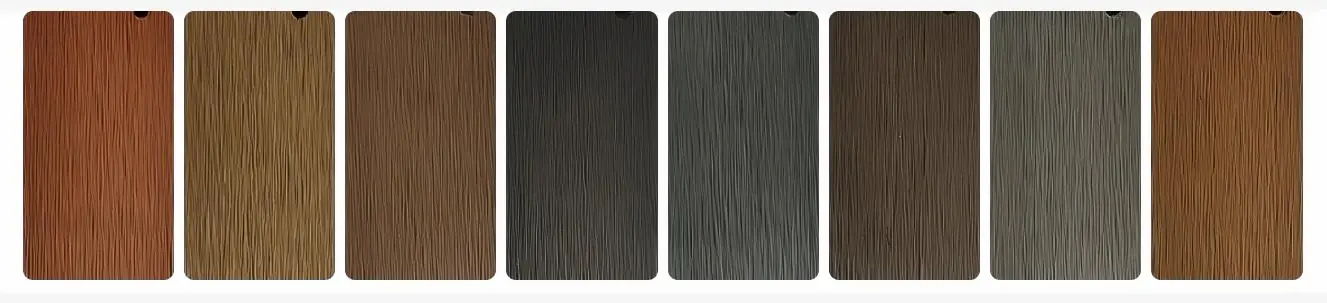

Color: cedar, charcoal, chocolate, coffee, grey, light gray, red wood, wood, or customized

Surface Treatment: Brushed or Sanding

Accessories: Joist, L angle strip, screw, expansion screw

Service life: 15 years,Dimensional Stability

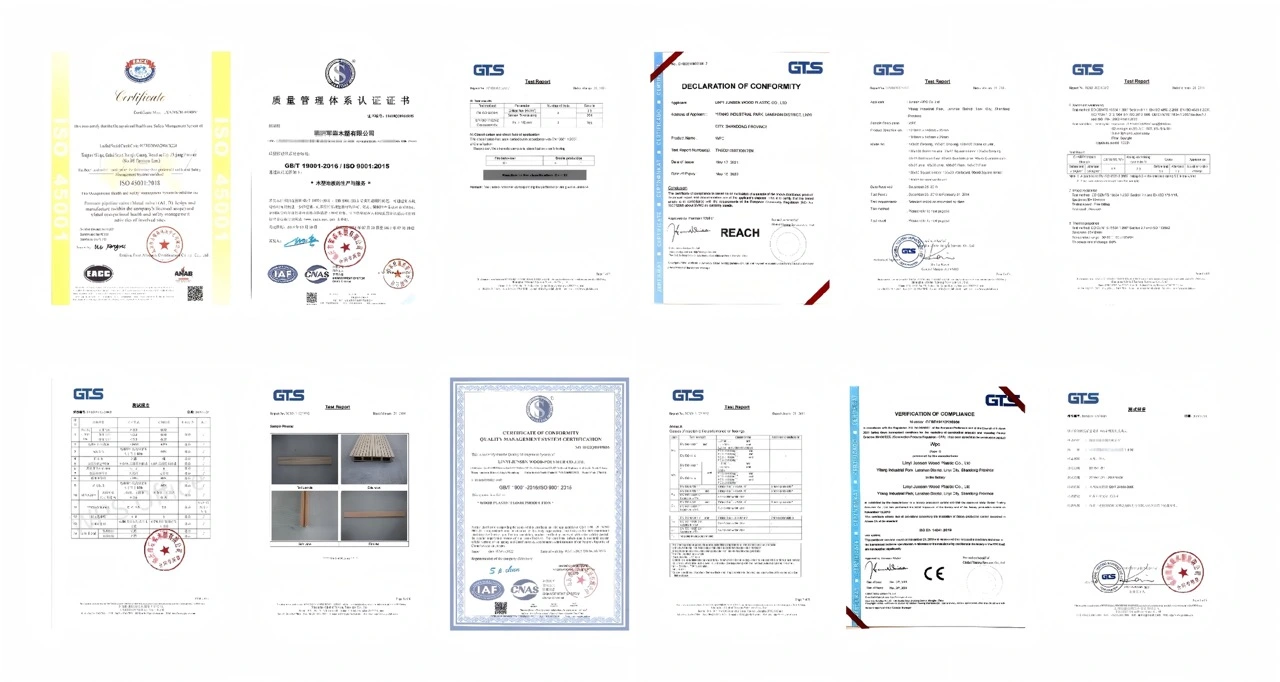

Certificates: FSC, CE, ISO 90012008, SGS

Maintenance: Requires no painting, no glue, low maintenance

Packaging: We use PE film and wood pallet & panel to package

Application: houses, exterior walls, garden rooms, roofs, residential, outdside of buildings,supermarket, villal, cottage house, swimming pool, outdoor garden,Living Room, Bedroom, Hallways, Offices, Bathrooms, Kitchens, Hotels, Retail Spaces, Conference Rooms, etc

WPC Horizontal Cladding (Horizontal Cladding Panels) : Focusing on Horizontal Decoration Scenarios, a Professional Material with Stability and Smooth Aesthetics

In building horizontal decoration scenarios, materials need to meet both "horizontal splicing fluency" and "long-term stress stability"—traditional horizontal decorative materials either have obvious splicing gaps that affect aesthetics, or are prone to breakage due to insufficient horizontal load-bearing capacity. As a wood-plastic composite material specially developed for horizontal scenarios, WPC Horizontal Cladding (Horizontal Cladding Panels) takes "horizontal structure optimization" as its core. Through high-precision horizontal splicing design and enhanced substrate formula, it combines the natural texture of wood fibers with the stable performance of polymer materials. It can achieve horizontal seamless splicing and maintain structural stability in scenarios such as long-term horizontal load-bearing and treading. It is widely used in various indoor and outdoor horizontal decoration and functional areas, providing an integrated "decorative aesthetics + structural stability" solution for building horizontal surfaces and filling the gap of traditional materials in horizontal scenario applications.

Major Advantages of the Product

✅ High-precision Horizontal Splicing, Smooth Visual Effect Without Breakpoints:

Horizontal Cladding Panels adopts a dual splicing design of "beveled lock + flat joint fitting". The sides of the panels are precision-ground, with a splicing error of ≤0.1mm; the beveled lock can realize tight horizontal engagement of the panels, and the flat joint fitting technology makes the splicing gap width ≤0.3mm, which is almost seamless visually. After horizontal paving, a coherent and smooth decorative surface is formed, solving the pain points of obvious splicing gaps and easy dust accumulation of traditional horizontal materials. It is especially suitable for large-area horizontal wall and surface decoration, improving the overall delicacy of the space.

✅ Strong Horizontal Load-bearing Performance, Outstanding Durability:

Aiming at the characteristics of horizontal scenarios being prone to treading and heavy pressure, it optimizes material density and strengthens the structure. Its horizontal flexural strength is ≥18MPa, compressive strength is ≥25MPa, and it can bear a uniform load of 300kg per square meter ; after 10,000 horizontal treading tests , the panels have no deformation or cracks, and can be used for a long time in high-frequency load-bearing horizontal scenarios such as plank roads and platforms, with a service life of 15-20 years.

✅ Anti-slip and Wear-resistant, Suitable for High-frequency Use Scenarios:

The surface of it is treated with "texture embossing + anti-slip coating". The surface friction coefficient is ≥0.6 (dry state) and ≥0.5 (wet state), meeting the national anti-slip standard (≥0.5). Even in wet garage ramps and outdoor plank road scenarios, it can effectively prevent people from slipping; at the same time, the surface hardness is ≥4H, with excellent wear resistance. After 500 revolutions of wear test (load 500g), the wear amount is ≤0.02g, which can resist daily friction and scratches, and is suitable for high-frequency use horizontal areas such as shopping mall corridors and garages.

✅ Horizontal Drainage Design, Suitable for Outdoor Scenarios:

Aiming at the problem of easy water accumulation on outdoor horizontal surfaces, it is preset with horizontal drainage grooves (groove width 3mm, spacing 50mm) at the bottom of the panel. Rainwater or accumulated water can be quickly discharged horizontally through the drainage grooves, avoiding accumulation on the surface and causing penetration; at the same time, the edge of the panel is designed with a 5° inclined water guide angle to further guide water to the drainage area, greatly reducing the water seepage risk of outdoor horizontal surfaces, especially suitable for areas with frequent rainy seasons and large rainfall.

✅ Environmental Protection and Odor-free, Safe for Multi-scenario Application:

Made of recycled polymer materials and natural wood fibers, there is no formaldehyde or heavy metal emission during the production process. The formaldehyde emission is ≤0.012mg/m³, meeting the national E0-level environmental protection standard; the surface coating uses environmentally friendly water-based anti-slip agents, with no volatile organic compounds (VOC), and no pungent odor after installation. It can be directly used in horizontal wall panels in children's activity areas and kitchen countertops and other scenarios with high environmental protection requirements, ensuring the health and safety of users.

✅ Modular Paving, High Construction Efficiency:

It adopts a standardized module design. The conventional lengths are 2.4m and 3.6m, and the widths are 200mm and 300mm. It can be flexibly cut according to the size of the horizontal area without customizing special-shaped panels; the horizontal lock of the panel is easy to install, and a single person can complete 15-20㎡ of paving per hour, with construction efficiency 40% higher than that of traditional horizontal materials; in addition, no complex base treatment is required, and construction can be carried out only with a flat base, which greatly shortens the horizontal decoration construction period and reduces labor costs.

✅ Application of 8 Colors

Horizontal Cladding Panels provides 8 practical colors suitable for horizontal scenarios, covering diverse decorative and functional needs: light gray and dark gray are suitable for garage ramps and commercial space horizontal wall panels in modern minimalist style, combining anti-slip and aesthetics; light oak color and walnut color are suitable for indoor wall waistlines and home balcony horizontal surfaces, creating a natural and warm atmosphere; off-white and milk white are suitable for horizontal wall panels in public spaces such as hospitals and schools, presenting a clean and tidy visual effect; cyan gray and dark brown are suitable for outdoor plank roads and landscape platforms, harmoniously integrating with the natural environment, meeting the style and functional positioning of different horizontal scenarios.

OEM and ODM Services

To meet the horizontal scenario needs and brand positioning of different customers, we provide customized OEM and ODM services, focusing on "horizontal function customization" and "scenario adaptation optimization".

In terms of OEM services, customers can provide brand logos, product specifications (length, width, thickness), surface anti-slip level and color requirements. We will adjust the horizontal lock structure and anti-slip coating formula according to customer needs, produce in strict accordance with customer standards, and provide supporting horizontal fixing parts, anti-slip pads at the same time, helping customers quickly launch their own brand of Horizontal Cladding Panels products without investing in horizontal technology R&D costs.

In terms of ODM services, our R&D team can provide a full-process service from "product structure design" to "installation plan optimization" according to the customer's specific horizontal scenarios (such as extra-wide horizontal surfaces, ramps with high anti-slip requirements, outdoor platforms in low-temperature areas). For example, for extra-wide horizontal surfaces (width ≥1.5m), we can develop "reinforced horizontal keels + segmented splicing" products; for low-temperature area scenarios, we optimize the "anti-freezing formula" to ensure horizontal structural stability in -30℃ environment. Customers can directly adopt mature solutions or put forward personalized modifications, and the R&D cycle is shortened to 25-40 days to quickly respond to the needs of segmented markets.

Relevant Qualification Certifications

To ensure the horizontal performance and compliance of the product, Horizontal Cladding Panels has obtained a number of professional qualification certifications: domest ically, it has passed the standard certification of GB/T 24137-2021 "Wood-plastic Composite Panels", and its horizontal flexural and compressive properties are better than the standard requirements; it has obtained the "Anti-slip Decorative Material Certification" issued by the China Building Materials Federation (with qualified friction coefficient), which can be used in horizontal scenarios with high anti-slip requirements; it has passed the wear resistance and freeze-thaw resistance tests of the National Building Material Testing Center (no abnormality after 50 cycles of -30℃ to 20℃), ensuring adaptation to diverse environments. Internationally, it has passed the EU CE certification (in line with EN 14915 standard, applicable to horizontal building components) and the US ASTM D7031 standard certification (horizontal performance standard for wood-plastic panels), meeting the strict requirements of the European and American markets for horizontal materials; at the same time, it has passed the RoHS and REACH environmental protection tests and anti-slip performance tests of SGS, ensuring the product's safety and compliance, and providing qualification support for customers' domestic and foreign projects.

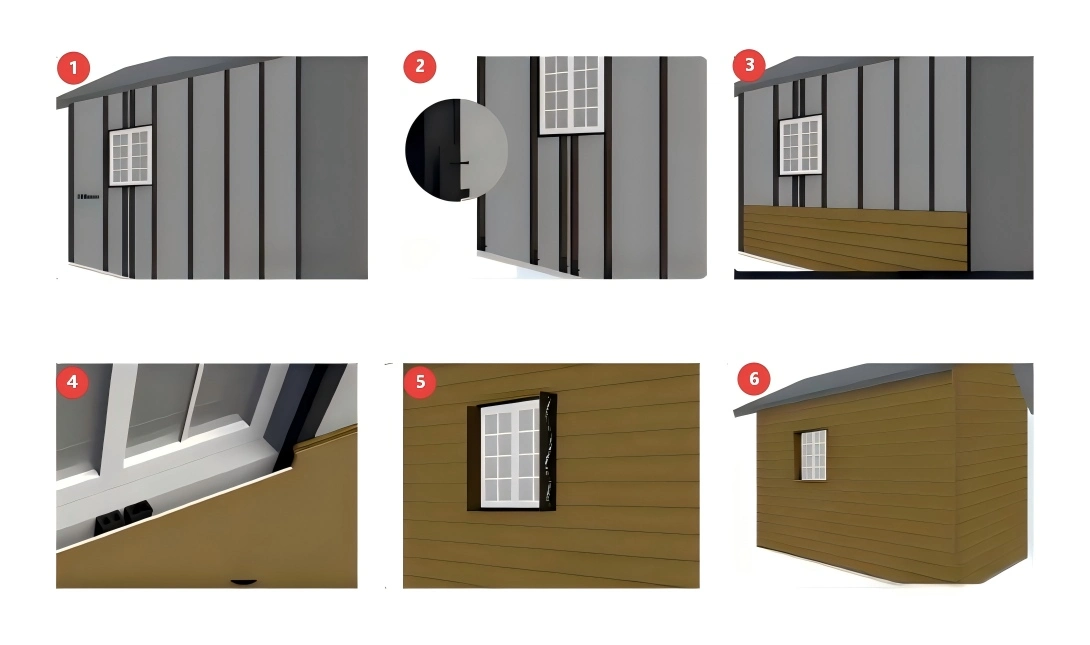

Installation Steps

Before installing the wall panel,please confirm the wall is smooth and strong enough.Plan the layout of the cladding panels,Measure the dimensions of the wall and calculate the number of Horizontal Cladding Panels needed to cover the entire surface area.

- Attach the joists vertically along the bottom edge of the wall. Nail the expansion screw to make it stable enough. Notice: Staggered installation needs two pieces of fists on the joint of the two panels.

- Fix the start clip, use electric drilling to pre-drill, and fix it with a stainless steel screw. Install all the start clips on the bottom in the same way. Notice: The screws must be stainless steel screws.

- Install the first piece of the wall panel and fix it with stainless steel screws. Continue as above instruction: put wall panels on,pre-drill, and fix stainless steel screws one by one to finish the whole wall installation.

- When the window is encountered during installation, I will put a small piece of wood between the joist and the wall panel. Pre-drill and fix with stainless steel screws, then continue installing the wall panel.

- Gelatinize the wall panel around the window frame with styrofoam and fix it with stainless steel screws. Install the L corner, and cut the end of the two corners at the angle of 45°.

- Continue installing wpc cladding row by row until the entire wall surface is covered. Trim the last row of panels to fit. Install trim at the corner

Conclusion

With "horizontal scenario-specific design" as its core competitiveness, WPC Horizontal Cladding (Horizontal Cladding Panels) provides a professional solution for building horizontal decoration and functional scenarios by virtue of its advantages such as high-precision splicing, strong horizontal load-bearing, anti-slip and wear resistance, as well as customized OEM/ODM services and comprehensive qualification certifications. It not only solves the pain points of traditional horizontal materials such as "rough splicing, easy damage, and high maintenance costs" but also achieves a perfect balance between "decorative aesthetics" and "functional practicality", allowing horizontal areas to have both smooth visual beauty and long-term resistance to use pressure.

FAQ

1.How do these panels compare to wood or PVC?

Our products outperform wood in durability and PVC in strength. They resist warping, require no maintenance, and offer fire-rated options.

2.What certifications do you offer?

We hold FSC, CE, ISO 9001, and SGS certifications. Panels comply with EU/US/APAC building codes.

3.What's the MOQ for custom projects?

Minimum order is 20GP. Contact us for bulk discounts.

Contact Us

📧 Email: info@durable-fences.com

📞 Phone: +86 18066962697

💬 WhatsApp: +86 18066962697

🟢 WeChat: +86 18066962697

In the future, we will continue to deepen the research and development of horizontal scenario technology, optimize product performance for more special horizontal needs (such as extra-wide horizontal countertops, horizontal materials in high-temperature and high-humidity areas), and improve the customized service system to provide more demand-oriented WPC Horizontal Cladding (Horizontal Cladding Panels) products and services for global customers. We look forward to working together to promote the development of the building horizontal decoration industry towards a "more refined, more durable, and more adaptable" direction, and jointly create more high-quality horizontal decoration projects.

Get a Quote for Your Fencing Project Today