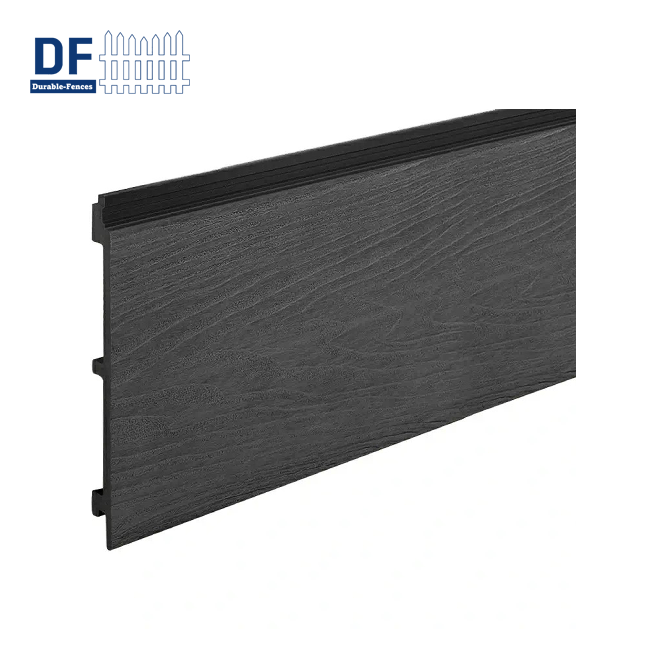

Slatted Cladding Composite

Length:2.2m,2.9m,3.6m, 5m or customized

Material: 30%HDPE(Grade A Recycled HDPE)+ 60% Wood fiber component + 10% chemical additives

Thickness:17mm,19mm,21mm,26mm,31mm etc.

Recyclable: 100% Recyclable

Profile: Solid/Square Hollow/Great Wall Panel

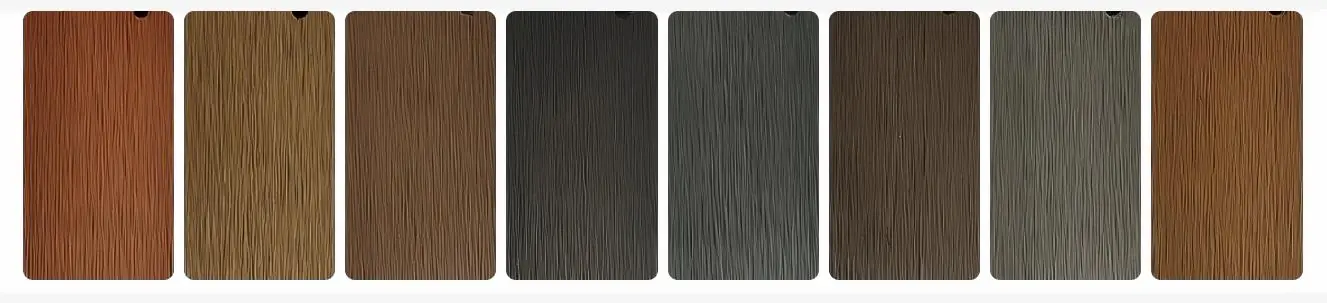

Color: cedar, charcoal, chocolate, coffee, grey, light gray, red wood, wood, or customized

Surface Treatment: Brushed or Sanding

Accessories: Joist, L angle strip, screw, expansion screw

Service life: 15 years,Dimensional Stability

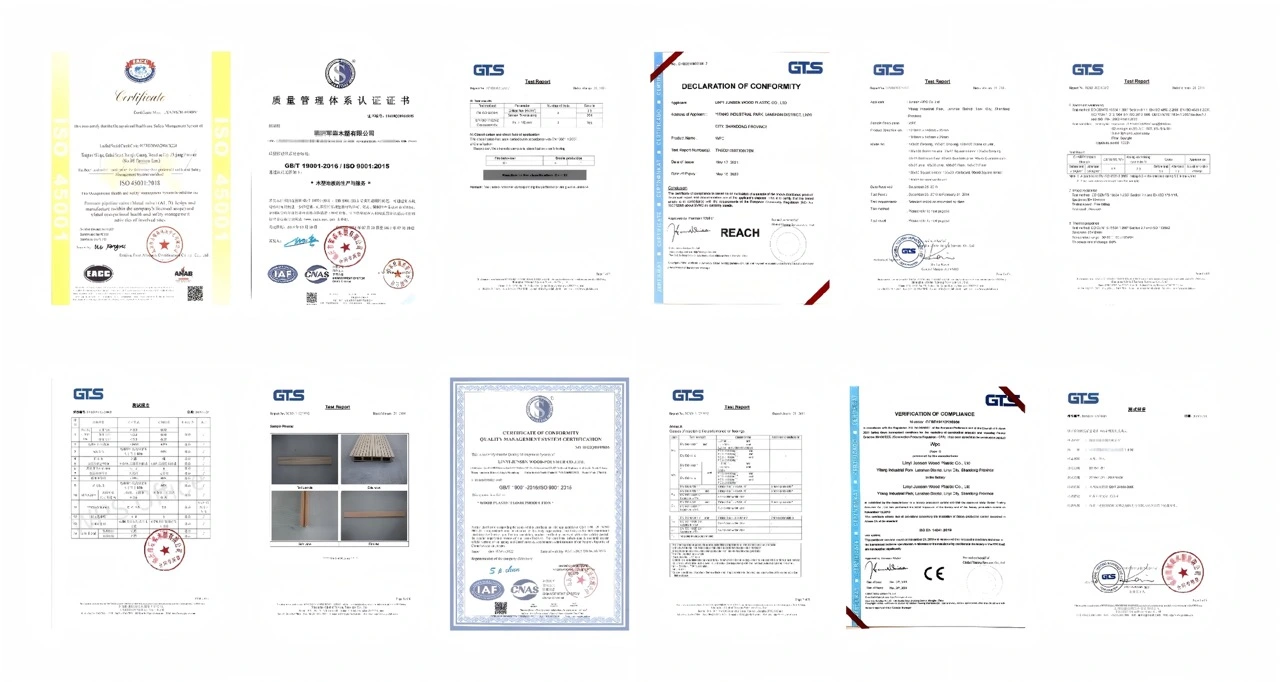

Certificates: FSC, CE, ISO 90012008, SGS

Maintenance: Requires no painting, no glue, low maintenance

Packaging: We use PE film and wood pallet & panel to package

Application: houses, exterior walls, garden rooms, roofs, residential, outdside of buildings,supermarket, villal, cottage house, swimming pool, outdoor garden,Living Room, Bedroom, Hallways, Offices, Bathrooms, Kitchens, Hotels, Retail Spaces, Conference Rooms, etc

WPC Slatted Cladding (Slatted Cladding Composite) : Creating Hierarchical Decoration, an Innovative Material with Flexible Adaptability and Natural Texture

In the current era where architectural decoration pursues "lightness" and "hierarchical beauty", traditional monolithic cladding tends to make the space look depressing, while ordinary wooden slats face problems of easy deformation and difficult maintenance. As a wood-plastic composite material centered on a "slatted structure", WPC Slatted Cladding (Slatted Cladding Composite) integrates the natural texture of wood fibers and the stable performance of polymer materials into a slender slat design. Each slat has a width of only 30-120mm, and can be arranged with adjustable spacing and staggered heights to create a transparent and flexible hierarchical decorative effect. It is widely used in indoor ceilings, feature walls, commercial space walls, outdoor sunshades, landscape fences and other scenarios. It can not only replace traditional wooden slats to solve maintenance problems, but also break the visual limitations of monolithic cladding, injecting "light hierarchical beauty" into architectural decoration, and becoming a popular choice for designers to create personalized spaces.

Major Advantages of the Product

✅ Hierarchical Decoration, Flexible Visual Effect:

Slatted Cladding Composite adopts a slender slat structure. During installation, the slat spacing can be flexibly adjusted to form a "combination of virtual and real" visual effect, making the space more transparent and light; at the same time, it supports arrangement methods such as "staggered heights" and "color gradient". For example, alternating light oak and dark walnut slats, or creating a three-dimensional shape through the height difference of slats, can easily create hierarchical beauty in various styles such as simple modern, natural fresh, and industrial retro. Its visual expression is far superior to traditional monolithic cladding.

✅ Lightweight Slats, Flexible and Convenient Installation:

Each it weighs only 0.2-0.5kg/m, much lighter than wooden slats of the same size. No heavy installation equipment is needed, and it can be operated by one person with hands; the top of the slat is preset with a card slot and the bottom with a buckle, which can be directly clipped to the special keel without additional drilling and fixing. The installation efficiency is more than 50% higher than that of traditional wooden slats; in addition, the slat length supports customization, which can adapt to walls and ceilings of different heights, even curved surface scenarios, greatly reducing the installation difficulty of complex spaces.

✅ Anti-deformation and Anti-cracking, Stable Long-term Performance:

Aiming at the problem that wooden slats are prone to bending and cracking due to dry and wet changes, it controls the water absorption rate below 1% and the wet expansion rate ≤0.3% by optimizing the material formula, and will not deform even in humid environments; at the same time, anti-aging components are added to resist fading and embrittlement caused by ultraviolet radiation when used outdoors. Tests show that after 6 years of outdoor use, the color retention rate of slats reaches more than 80%, and the structural strength attenuation rate is less than 5%, maintaining flatness and stability for long-term use.

✅ Ventilation and Breathability, Moisture-proof and Mildew-proof:

It structure naturally has "ventilation gaps". After installation, air can circulate freely through the slat gaps, effectively reducing moisture accumulation inside walls and ceilings, and avoiding mold growth due to moisture; it is especially suitable for humid scenarios such as bathroom ceilings and basement walls. Compared with airtight monolithic cladding, it can reduce the risk of mold growth by more than 90%, keeping the space dry and fresh.

✅ Environmental Protection and Durability, Low Maintenance Cost:

It is produced with recycled polymer materials and waste wood fibers. Producing 1 ton of it can reduce 400kg of plastic waste, in line with the concept of green environmental protection; the product surface is smooth, and daily cleaning only requires using a vacuum cleaner or damp cloth to clean the dust in the slat gaps, without regular painting and waxing like wooden slats; in addition, the slats are scratch-resistant and corrosion-resistant, and not easy to be damaged even by slight collisions. The annual maintenance cost is less than 5% of that of wooden slats, making it more economical for long-term use.

✅ Multi-scenario Adaptability, Strong Function Expansion:

It can not only be used for decoration, but also expand its application in combination with functional needs - for example, in outdoor scenarios, the sunshade and rainproof functions can be realized by adjusting the tilt angle of slats; in indoor scenarios, light strips can be embedded in the slat gaps to create an atmosphere effect of "light and shadow linkage"; it can even be used as a partition, and the "semi-transparent" partition effect can be realized by adjusting the slat density, taking into account both privacy and lighting. Its functional adaptability is far superior to cladding materials for a single decorative purpose.

✅ Application of 8 Colors

Slatted Cladding Composite provides 8 mainstream colors suitable for different scenarios, covering diverse style needs: light oak color and ash wood color are suitable for creating natural and fresh indoor ceilings and feature walls, adapting to pastoral and Japanese-style spaces; dark walnut color and carbon black are suitable for industrial and retro scenarios, such as bar walls and cultural and creative space ceilings; off-white and light gray are suitable for modern minimalist commercial space walls and residential living room feature walls, enhancing the brightness of the space; cyan gray and light brown are suitable for outdoor landscape fences and sunshades, harmoniously integrating with the natural environment, meeting the style positioning of different scenarios.

OEM and ODM Services

To meet the personalized needs and market positioning of different customers, Slatted Cladding Composite provide customized OEM and ODM services, focusing on "slat characteristic customization" and "scenario scheme optimization".

In terms of OEM services, customers can provide brand logos, slat specifications (width, thickness, length), color and texture requirements. We will adjust the production parameters according to the needs, such as customizing extra-wide slats of 120mm or short slats of 1m for customers, and provide supporting special keels and fixing buckles at the same time, helping customers quickly launch their own brand products without investing in slat structure R&D costs.

In terms of ODM services, our R&D team can provide a full-process service from "slat structure design" to "installation scheme formulation" according to the customer's specific scenarios (such as curved ceilings, outdoor sunshades, light and shadow partitions). For example, for curved ceiling scenarios, we develop "flexible WPC slats" to achieve seamless bending; for light and shadow partition scenarios, we optimize the slat cross-section design to improve light transmittance. Customers can directly adopt mature schemes or put forward personalized modifications, and the R&D cycle is shortened to 25-40 days to quickly respond to the needs of segmented markets.

Relevant Qualification Certifications

To ensure product quality and compliance, Slatted Cladding Composite has obtained a number of authoritative qualification certifications: domestically, it has passed the standard certification of GB/T 24137-2021 "Wood-plastic Composite Panels", and the bending strength, anti-aging performance and other indicators of slats are better than the standard requirements; it has obtained the China Green Building Material Product Certification (two-star level), which can be used for green building indoor and outdoor decoration projects; it has passed the mildew-proof test (mold growth level 0) of the National Furniture and Indoor Environmental Quality Supervision and Inspection Center, ensuring safe use in humid scenarios. Internationally, it has passed the EU CE certification (in line with EN 15534 standard) and the US ASTM D6662 standard certification, meeting the strict requirements of the European and American markets for wood-plastic materials; at the same time, it has passed the RoHS and REACH environmental protection tests of SGS, ensuring that the product has no harmful substances and meets international environmental protection regulations, providing qualification support for customers' domestic and foreign projects.

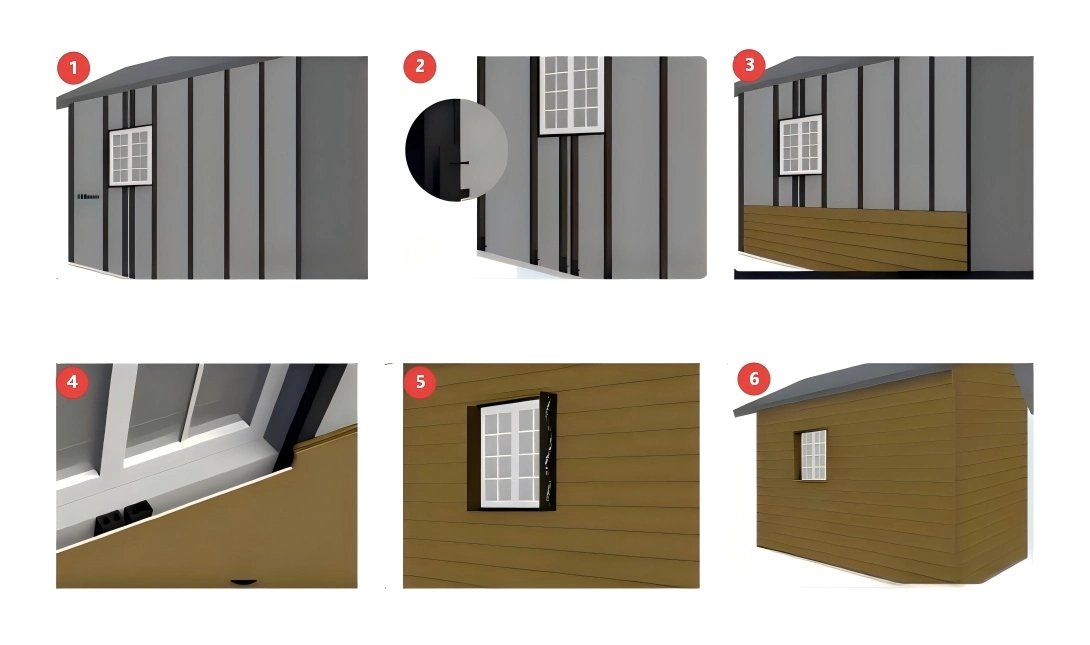

Installation Steps

Before installing the wall panel,please confirm the wall is smooth and strong enough.Plan the layout of the cladding panels,Measure the dimensions of the wall and calculate the number of Slatted Cladding Composite needed to cover the entire surface area.

- Attach the joists vertically along the bottom edge of the wall. Nail the expansion screw to make it stable enough. Notice: Staggered installation needs two pieces of fists on the joint of the two panels.

- Fix the start clip, use electric drilling to pre-drill, and fix it with a stainless steel screw. Install all the start clips on the bottom in the same way. Notice: The screws must be stainless steel screws.

- Install the first piece of the wall panel and fix it with stainless steel screws. Continue as above instruction: put wall panels on,pre-drill, and fix stainless steel screws one by one to finish the whole wall installation.

- When the window is encountered during installation, I will put a small piece of wood between the joist and the wall panel. Pre-drill and fix with stainless steel screws, then continue installing the wall panel.

- Gelatinize the wall panel around the window frame with styrofoam and fix it with stainless steel screws. Install the L corner, and cut the end of the two corners at the angle of 45°.

- Continue installing wpc cladding row by row until the entire wall surface is covered. Trim the last row of panels to fit. Install trim at the corner

Conclusion

With "hierarchical decoration" as its core advantage, WPC Slatted Cladding (Slatted Cladding Composite) breaks the decorative limitations of traditional cladding and injects light beauty into architectural spaces by virtue of its flexible visual effect, flexible installation method, stable product performance, as well as customized OEM/ODM services and comprehensive qualification certifications. Whether it is an indoor ceiling pursuing transparency, a commercial space creating a personalized feature wall, or an outdoor landscape requiring both aesthetics and durability, it can provide an adaptive solution to balance decorative needs and practical value.

FAQ

1. How quickly can I install product?

Its interlocking system and pre-drilled holes cut installation time by 40%—no specialized tools needed.

2. Is it suitable for coastal areas?

Yes! The waterproof core resists salt spray, humidity, and mold growth.

3. Can I get custom colors?

Absolutely. We match Pantone codes or develop exclusive shades for branded projects.

4. Are fire-rated panels heavier?

No—they maintain the same lightweight profile (2.2kg/m²) as standard panels.

Contact Us

📧 Email: info@durable-fences.com

📞 Phone: +86 18066962697

💬 WhatsApp: +86 18066962697

🟢 WeChat: +86 18066962697

In the future, we will continue to optimize the slat structure design, develop more cross-sectional shapes (such as curved slats, special-shaped slats) and functional products (such as sound-absorbing slats, heat-insulating slats), and improve the customized service system to provide more demand-oriented WPC Slatted Cladding (Slatted Cladding Composite) products and services for global customers. We look forward to working together to promote the development of the architectural decoration industry towards a "lighter, more diverse and more aesthetic" direction, and jointly create more high-quality decorative projects full of hierarchical beauty.

Get a Quote for Your Fencing Project Today