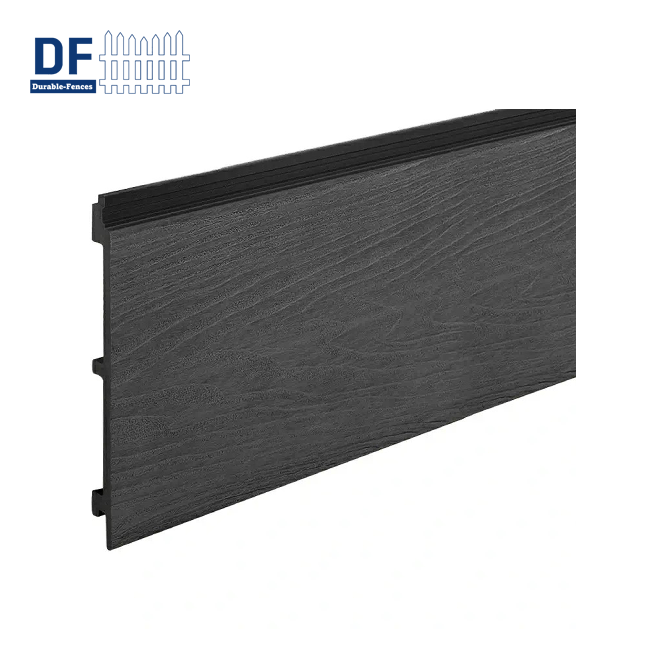

Waterproof Exterior Cladding

Length:2.2m,2.9m,3.6m, 5m or customized

Material: 30%HDPE(Grade A Recycled HDPE)+ 60% Wood fiber component + 10% chemical additives

Thickness:17mm,19mm,21mm,26mm,31mm etc.

Recyclable: 100% Recyclable

Profile: Solid/Square Hollow/Great Wall Panel

Color: cedar, charcoal, chocolate, coffee, grey, light gray, red wood, wood, or customized

Surface Treatment: Brushed or Sanding

Accessories: Joist, L angle strip, screw, expansion screw

Service life: 15 years,Dimensional Stability

Certificates: FSC, CE, ISO 90012008, SGS

Maintenance: Requires no painting, no glue, low maintenance

Packaging: We use PE film and wood pallet & panel to package

Application: houses, exterior walls, garden rooms, roofs, residential, outdside of buildings,supermarket, villal, cottage house, swimming pool, outdoor garden,Living Room, Bedroom, Hallways, Offices, Bathrooms, Kitchens, Hotels, Retail Spaces, Conference Rooms, etc

WPC Waterproof Cladding(Waterproof Exterior Cladding): Focusing on Waterproof Protection, a Professional Decorative Material for Long-lasting Building Durability

In architectural decoration, humid environments (such as bathrooms, kitchens, basements, and outdoor pool surroundings) have always been a difficulty in material selection—traditional decorative materials are prone to mildew, rot, and deformation due to water seepage, which not only affects the appearance but also shortens the service life of buildings. As a professional wood-plastic composite material developed for waterproofing needs, WPC Waterproof Cladding(Waterproof Exterior Cladding) takes "high waterproofness" as its core design goal. Through a special waterproof formula and multi-layer structural technology, it deeply combines the natural texture of wood fibers with the strong waterproof performance of polymer materials. It can maintain stable performance in environments with long-term water contact or humidity, without seepage or damage. It is widely used in bathroom walls, kitchen countertop facades, basement walls, outdoor water-facing platforms, pool surrounding decorations and other scenarios, providing an integrated "waterproof + decoration" solution for moisture-prone areas of buildings and filling the gap of traditional decorative materials in humid environment applications.

Major Advantages of the Product

✅ Multi-layer Waterproof Structure, Almost Zero Water Seepage Rate:

Waterproof Exterior Cladding adopts a three-layer waterproof structure of "surface waterproof film + core layer waterproof substrate + bottom moisture-proof coating"—the surface layer is treated with a nano-level waterproof coating to form a dense water-repellent barrier, and water droplets can roll off directly when falling on the surface without penetration or hanging; the core layer is made of high-density waterproof polymer materials combined with wood fibers, with a moisture content controlled below 2%, blocking water penetration from the substrate level; the bottom moisture-proof coating further isolates the reverse penetration of base moisture. Tests show that the product's 24-hour water absorption rate is only 0.05%, far lower than the national standard, and the water seepage rate is almost zero, which can be used in long-term immersion in water.

✅ Mildew and Corrosion Resistance, Adapting to Harsh Humid Environments:

Humid environments are prone to mildew and bacteria growth, and may have chemical erosion such as detergents and disinfectants. It is added with special mildew inhibitors and anti-corrosion components, which can effectively inhibit the growth of mildew and bacteria, and has good tolerance to common acid and alkali substances (such as white vinegar, soapy water, disinfectant). Long-term contact will not cause surface corrosion, discoloration, or structural damage, especially suitable for bathrooms, kitchens, laboratories and other special humid scenarios with chemical erosion risks.

✅ Temperature Difference and Aging Resistance, Suitable for All-climate Scenarios:

Different from the problem that ordinary waterproof materials are prone to cracking and aging under extreme temperature differences, it can withstand extreme temperature changes from -40℃ to 80℃ through formula optimization, and there is no cracking, deformation, or delamination after 50 cycles of thermal cycle testing; at the same time, the surface layer is added with anti-ultraviolet additives, which can resist ultraviolet aging when used outdoors, avoiding the decline of waterproof performance and appearance fading due to long-term sun exposure. It is suitable for cold and humid areas in the north and can also meet the use needs of high-temperature and high-humidity environments in the south.

✅ Easy to Clean and Maintenance-free, Reducing Usage Costs:

In humid environments, the surface of traditional materials is prone to scale and stains, which are difficult to clean, and regular waterproof repairs are required. The surface of it is smooth and water-repellent, and scale and stains can be removed by wiping with clean water or ordinary detergents without residue or traces; moreover, the product's waterproof performance is stable, with a service life of 15-20 years, and no additional waterproof agents or waterproof repairs are needed during the period, which greatly reduces the workload of cleaning and maintenance and lowers long-term usage costs.

✅ Environmental Protection, Safety and Odor-free, Suitable for Sensitive Scenarios:

It is made of environmentally friendly waterproof resin and recycled wood fibers, without formaldehyde, heavy metals, or volatile organic compounds. The formaldehyde emission is ≤0.01mg/m³, far better than the national standard; there is no toxic wastewater or waste gas emission during the production process, which meets the national environmental protection production requirements. The product has no pungent odor after installation, and can be directly used in sensitive scenarios such as children's room bathrooms and elderly room bathrooms with high environmental safety requirements, providing a healthy and safe environment for users.

✅ Lightweight and Easy to Cut, Suitable for Complex Shapes:

Despite its strong waterproof performance, the weight of it is still controlled at 6-8kg/㎡, much lighter than traditional waterproof stone (25-30kg/㎡) and ceramic tiles (20-25kg/㎡), which will not increase the load-bearing burden of walls or bases, especially suitable for the renovation of humid areas in old buildings. At the same time, the product has moderate hardness and can be cut, chamfered, and holed with ordinary electric saws and wallpaper knives, easily adapting to complex shapes such as bathroom corners and pipeline surroundings. No professional waterproof construction team is needed, and ordinary decoration personnel can operate it, reducing the construction threshold.

✅ Application of 8 Colors

Waterproof Exterior Cladding provides 8 practical colors suitable for humid scenarios, balancing waterproof function and visual coordination: light beige and pure white are suitable for spaces that require a bright and clean atmosphere such as bathrooms and kitchens, and can enhance the transparency of the space when matched with lighting; light gray and dark gray are suitable for modern minimalist style basements and outdoor water-facing platforms, and look more calm when matched with stone and metal elements; light blue and cyan green fit the "water theme" design of pool surroundings and bathroom spaces, creating a fresh and natural visual effect; light oak color and dark walnut color can create a warm and natural atmosphere in kitchens and basements, suitable for new Chinese and pastoral style designs, meeting the style needs of different humid scenarios.

OEM and ODM Services

To meet the waterproof scenario needs and brand positioning of different customers, Waterproof Exterior Cladding provide customized OEM and ODM services, focusing on "waterproof performance customization" and "scenario adaptation optimization".

In terms of OEM services, customers can provide brand logos, product specifications (thickness 6-12mm, width 180-320mm), and waterproof level requirements (such as ordinary moisture-proof, deep waterproof, immersion-level waterproof). We will adjust the waterproof formula and structure according to customer needs, produce in strict accordance with customer standards, and provide supporting waterproof installation accessories (such as special waterproof glue, sealing strips) and customized packaging to help customers quickly launch their own brand of professional waterproof cladding products without investing in waterproof technology R&D costs.

In terms of ODM services, our R&D team can provide a full-process service from "waterproof performance R&D" to "product design" and then to "installation plan optimization" according to the customer's specific scenarios (such as high-temperature and high-humidity southern bathrooms, low-temperature and humid northern basements, and long-term immersion pool surroundings). For example, for pool surrounding scenarios, we can develop "chlorine corrosion resistance + anti-ultraviolet" dual-effect waterproof products; for basement scenarios, we can optimize the "moisture-proof + mildew-proof" dual performance. Customers can directly adopt mature solutions or put forward personalized modifications, and the R&D cycle is shortened to 30-45 days to quickly respond to the needs of segmented markets.

Relevant Qualification Certifications

To ensure the product's waterproof performance and compliance, Waterproof Exterior Cladding has obtained a number of professional qualification certifications: domestically, it has passed the certification of GB/T 1733-1993 "Determination of Water Resistance of Paint Films" (no abnormality after 240 hours of immersion) and GB/T 24128-2009 "Test Method for Mildew Resistance of Plastics" (Grade 0 mildew resistance), verifying the product's core waterproof and mildew-resistant performance; it has obtained the "Recommended Building Waterproof Material Product" certification issued by the China Building Waterproof Association, which can be used for the declaration of building waterproof projects; it has passed the thermal cycle resistance and chemical corrosion resistance tests of the National Building Material Testing Center, ensuring adaptation to diverse humid scenarios. Internationally, it has passed the EU CE certification (in line with EN 13445 standard, applicable to building materials in contact with water) and the US ANSI A118.10 standard certification (waterproof standard for tile and stone cladding), meeting the strict requirements of the European and American markets for waterproof materials; at the same time, it has passed the RoHS and REACH environmental protection tests of SGS and the FDA food contact level test (the surface layer can be in contact with food-grade detergents), ensuring the product's safety and compliance, and providing qualification support for customers' domestic and foreign projects.

Installation Steps

Before installing the wall panel,please confirm the wall is smooth and strong enough.Plan the layout of the cladding panels,Measure the dimensions of the wall and calculate the number of Waterproof Exterior Cladding needed to cover the entire surface area.

- Attach the joists vertically along the bottom edge of the wall. Nail the expansion screw to make it stable enough. Notice: Staggered installation needs two pieces of fists on the joint of the two panels.

- Fix the start clip, use electric drilling to pre-drill, and fix it with a stainless steel screw. Install all the start clips on the bottom in the same way. Notice: The screws must be stainless steel screws.

- Install the first piece of the wall panel and fix it with stainless steel screws. Continue as above instruction: put wall panels on,pre-drill, and fix stainless steel screws one by one to finish the whole wall installation.

- When the window is encountered during installation, I will put a small piece of wood between the joist and the wall panel. Pre-drill and fix with stainless steel screws, then continue installing the wall panel.

- Gelatinize the wall panel around the window frame with styrofoam and fix it with stainless steel screws. Install the L corner, and cut the end of the two corners at the angle of 45°.

- Continue installing wpc cladding row by row until the entire wall surface is covered. Trim the last row of panels to fit. Install trim at the corner

Conclusion

With "professional waterproofing" as its core competitiveness, WPC Waterproof Cladding(Waterproof Exterior Cladding) provides a reliable solution for the decoration of humid areas in buildings by virtue of its multi-layer waterproof structure, mildew and corrosion resistance, environmental protection and safety advantages, as well as scenario-based OEM/ODM services and comprehensive qualification certifications. It not only solves the pain points of traditional materials such as "poor waterproof performance and high maintenance costs" but also achieves a perfect balance between "waterproof function" and "decorative effect", allowing humid areas to maintain long-term durability while also having aesthetic texture.

FAQ

1.How does it handle extreme humidity or saltwater exposure?

The non-porous surface and UV inhibitors prevent swelling or corrosion, making it ideal for coastal areas.

2.Can I install it over existing walls?

Yes! The lightweight, interlocking system works on curved or flat surfaces without structural changes.

3.What's the lead time for 20,000 sq.ft orders?

Standard orders ship in 15 days. Custom projects require 3–4 weeks—contact us for expedited options.

Contact Us

📧 Email: info@durable-fences.com

📞 Phone: +86 18066962697

💬 WhatsApp: +86 18066962697

🟢 WeChat: +86 18066962697

In the future, we will continue to deepen the R&D of WPC Waterproof Cladding(Waterproof Exterior Cladding), optimize product performance for more special humid scenarios (such as marine climate areas and underground garage entrances and exits), and improve the customized service system to provide more demand-oriented waterproof cladding products and services for global customers. We look forward to working together to promote the quality upgrading of the architectural decoration industry in the application field of humid environments and jointly create "waterproof worry-free, beautiful and durable" architectural spaces.

Get a Quote for Your Fencing Project Today