WPC Composite Cladding

Length:2.2m,2.9m,3.6m, 5m or customized

Material: 30%HDPE(Grade A Recycled HDPE)+ 60% Wood fiber component + 10% chemical additives

Thickness:17mm,19mm,21mm,26mm,31mm etc.

Recyclable: 100% Recyclable

Profile: Solid/Square Hollow/Great Wall Panel

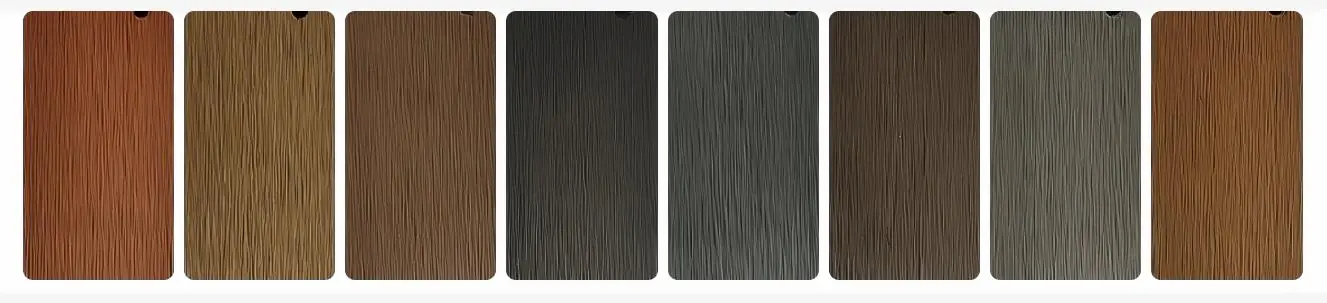

Color: cedar, charcoal, chocolate, coffee, grey, light gray, red wood, wood, or customized

Surface Treatment: Brushed or Sanding

Accessories: Joist, L angle strip, screw, expansion screw

Service life: 15 years,Dimensional Stability

Certificates: FSC, CE, ISO 90012008, SGS

Maintenance: Requires no painting, no glue, low maintenance

Packaging: We use PE film and wood pallet & panel to package

Application: houses, exterior walls, garden rooms, roofs, residential, outdside of buildings,supermarket, villal, cottage house, swimming pool, outdoor garden,Living Room, Bedroom, Hallways, Offices, Bathrooms, Kitchens, Hotels, Retail Spaces, Conference Rooms, etc

WPC Composite Cladding : Multi-material Synergy Empowers, an All-round Decorative Material Breaking the Limitations of Single Function

With the increasing diversification of architectural decoration needs, single-function cladding materials often struggle to meet the "one material for multiple scenarios" requirement—for example, outdoor scenarios need to balance weather resistance, anti-slip performance and sun protection, while high-end indoor spaces need to balance environmental protection, sound insulation and texture. WPC composite cladding innovatively adopts a "wood-plastic substrate + functional layer composite" structure. Taking modified WPC as the basic substrate, it integrates wear-resistant layers, sound insulation layers, antibacterial layers, anti-UV layers and other functional layers through processes such as hot-press compounding and co-extrusion compounding, realizing the superimposed empowerment of "basic performance + special functions". It breaks the limitation of traditional WPC cladding of "single function adapting to single scenario" and can be widely used in high-end residential whole-house customization (walls, floors, ceilings), commercial complex public areas, medical institution clean spaces, outdoor high-end landscape areas and other multi-scenarios. It provides a "one-stop material solution" for decoration projects with different needs, becoming a new type of material with both flexibility and versatility in the architectural decoration field.

Major Advantages of the Product

✅ Multi-material Composite, Comprehensive Performance Superposition:

WPC composite cladding adopts a "three-layer composite structure"—the bottom layer is a high-toughness WPC substrate , the middle layer is a functional layer compounded according to needs , and the surface layer is a wear-resistant and anti-fouling layer. The synergy of different materials enables the product to have multiple properties such as anti-aging, wear resistance, sound insulation and antibacterial at the same time. Compared with single-function cladding, the applicable scenarios are expanded by more than 3 times, and there is no need to replace materials for different functional needs, greatly reducing the project material selection cost.

✅ Flexible Scenario Adaptation, High Customization Degree:

Different from cladding materials with fixed functions, it supports "functional layer modular customization"—for medical institution scenarios, it can be compounded with antibacterial + easy-to-clean functional layers; for outdoor high-end landscapes, it can be compounded with anti-UV + salt-alkali resistant functional layers; for special spaces such as audio-visual rooms, it can be compounded with high-density sound insulation + flame-retardant functional layers. Through the flexible combination of functional layers, it can accurately match the core needs of different scenarios, solve the cumbersome problem of traditional cladding requiring "superposition for insufficient functions", and realize the efficient application of "one material adapting to multiple scenarios".

✅ Balancing Environmental Protection and Durability, More Economical Full Life Cycle:

The substrate uses recycled wood fibers and recycled polymer materials, and there is no glue bonding during the compounding process (using hot-press technology). The formaldehyde emission is ≤0.008mg/m³, far lower than the E0 standard; at the same time, the composite layer uses environmentally friendly materials with anti-aging and anti-decomposition properties. When used outdoors, the anti-UV aging grade reaches level 4 (no obvious fading in 5 years), and the service life indoors can reach more than 25 years. Compared with the traditional material model of "short-term replacement and multiple maintenance", the full-life cycle maintenance cost of it is reduced by 60%, with both environmental and economic value.

✅ Anti-fouling and Easy to Clean, Suitable for High-requirement Scenarios:

WPC composite cladding the nano anti-fouling coating compounded on the surface has "hydrophobic and oleophobic" properties, with a surface contact angle ≥110°. Stains such as soy sauce, oil and ink are not easy to adhere when dripping, and can be cleaned only by wiping with clean water without using detergents; at the same time, the coating has strong anti-permeability and will not cause pigmentation due to long-term contact with stains. It is especially suitable for restaurants, kindergartens, hospitals and other scenarios where stains are easy to occur, and the daily cleaning efficiency is increased by 80%.

✅ Anti-brittle Fracture at Low Temperature, Anti-deformation at High Temperature, Strong Environmental Adaptability:

Through the optimization of material formula and the improvement of composite technology, it still maintains stable performance in extreme environments—at low temperature, the substrate toughness retention rate is ≥85% without brittle fracture risk; at high temperature, the thermal deformation rate is ≤0.2% without bulging or warping; at the same time, the composite layer has moisture resistance and salt-alkali resistance. When used in coastal areas with high humidity and high salt spray, there is no corrosion or mildew within 5 years, and the environmental adaptation range covers different climate regions across the country.

✅ Strong Installation Compatibility, Suitable for Multiple Processes:

It supports two installation methods: "dry method + wet method"—dry installation can be connected with keels through special buckles, suitable for rough substrates, and can be disassembled and replaced at any time after installation; wet installation can be directly pasted with environmentally friendly adhesive, suitable for flat substrates, and the construction efficiency is 35% higher than that of traditional composite panels. At the same time, the product can be seamlessly connected with other decorative materials such as stone, metal and glass, and realize the natural transition of different materials through edge strips and transition pieces, meeting the design needs of complex spaces.

✅ Application of 8 Colors:

WPC composite cladding provides 8 colors suitable for different styles and scenarios, balancing aesthetics and functional needs: pearl white and light beige are suitable for medical institution clean spaces and high-end residential bedrooms, and when combined with antibacterial functional layers, they create a clean and sterile atmosphere; light oak and walnut colors are suitable for whole-house customization scenarios, and when combined with sound insulation layers, they are used for living room and bedroom walls, with both natural texture and quiet effect; dark gray and carbon black are suitable for commercial complex corridors and parking lot floors, and when combined with anti-slip + wear-resistant layers, they improve the durability of public areas; blue stone and sandstone colors are suitable for outdoor landscape areas, and when combined with anti-UV layers, they are used for landscape walls and platforms, integrating with the natural environment and maintaining long-term weather resistance, meeting the style positioning and functional requirements of different scenarios.

OEM and ODM Services

To meet the customer's brand positioning and personalized scenario needs, we provide "full-chain customized services", focusing on in-depth customization of "functional combination + brand output".

In terms of OEM services, customers can specify brand logos, product specifications (thickness 8-20mm, width 180-400mm), surface textures (stone-like, wood-like, solid color) and basic functional combinations (such as "wear-resistant + anti-fouling", "antibacterial + easy-to-clean"). We will adjust the composite process and material ratio according to the needs, and provide supporting installation accessories and brand packaging, helping customers quickly launch their own brand of standardized WPC composite cladding products without investing in composite process R&D costs.

In terms of ODM services, our R&D team can provide a full-process service of "functional demand analysis - material combination R&D - installation scheme design" for customers' special scenarios (such as nuclear power plant control rooms, food processing plant clean areas, outdoor venues in extremely cold areas). For example, for food processing plants, we develop a three-functional composite product of "antibacterial + acid and alkali resistant + easy-to-clean"; for extremely cold areas, we develop a composite structure of "anti-freezing + anti-UV + anti-slip". Customers can participate in the R&D process and put forward modification suggestions, and the R&D cycle is shortened to 35-50 days to quickly respond to the customized needs of special scenarios.

Relevant Qualification Certifications

To ensure product quality and multi-scenario compliance, WPC composite cladding has obtained a number of authoritative qualification certifications: domestically, it has passed the standard certification of GB/T 24137-2021 "Wood-plastic Composite Panels", and all performance indicators of the composite layer are better than the standard requirements; it has obtained the China Green Building Material Product Certification (three-star level), which can be used in green buildings and ultra-low energy consumption building projects; it has passed the antibacterial test (E. coli and Staphylococcus aureus antibacterial rate ≥99%) and sound insulation test (airborne sound insulation ≥30dB) of the National Furniture and Indoor Environmental Quality Supervision and Inspection Center; it has passed the flame retardant performance test (reaching GB 8624-2012 Grade B1), adapting to the fire protection requirements of public spaces. Internationally, it has passed the EU CE certification (in line with EN 15534 + EN ISO 105-X12 dual standards, covering weather resistance and environmental protection requirements) and the US ASTM D6662 + ASTM E90 dual standard certification (physical performance and sound insulation performance meet the standards); at the same time, it has passed the RoHS 2.0 and REACH 233 harmful substance tests of SGS, as well as the FDA food contact level certification (the surface layer can contact food-grade detergents), providing comprehensive qualification support for customers' high-end projects at home and abroad.

Installation Steps

Before installing the wall panel,please confirm the wall is smooth and strong enough.Plan the layout of the cladding panels,Measure the dimensions of the wall and calculate the number of panels needed to cover the entire surface area.

- Attach the joists vertically along the bottom edge of the wall. Nail the expansion screw to make it stable enough. Notice: Staggered installation needs two pieces of fists on the joint of the two panels.

- Fix the start clip, use electric drilling to pre-drill, and fix it with a stainless steel screw. Install all the start clips on the bottom in the same way. Notice: The screws must be stainless steel screws.

- Install the first piece of the wall panel and fix it with stainless steel screws. Continue as above instruction: put wall panels on,pre-drill, and fix stainless steel screws one by one to finish the whole wall installation.

- When the window is encountered during installation, I will put a small piece of wood between the joist and the wall panel. Pre-drill and fix with stainless steel screws, then continue installing the wall panel.

- Gelatinize the wall panel around the window frame with styrofoam and fix it with stainless steel screws. Install the L corner, and cut the end of the two corners at the angle of 45°.

- Continue installing wpc cladding row by row until the entire wall surface is covered. Trim the last row of panels to fit. Install trim at the corner

Conclusion

With "multi-material synergy", WPC composite cladding breaks the functional limitations of traditional cladding. Through performance superposition and scenario customization, it provides a more flexible and efficient material choice for architectural decoration. It not only solves the pain points of "multiple material replacements and difficult performance balance" in multi-scenario decoration, but also reduces the full-life cycle cost of the project with the advantages of environmental protection, durability and easy installation.

FAQ

1.How fast can product be installed?

Its interlocking design and pre-drilled holes cut labor time by 30% compared to traditional cladding.

2.Does it comply with fire safety standards?

Yes—our Class A2/B-rated panels meet EU (EN 13501) and North American (ASTM E84) regulations.

3.Can I use this in coastal areas?

Absolutely. The waterproof core and anti-corrosion additives resist saltwater damage.

Contact Us

📧 Email: info@durable-fences.com

📞 Phone: +86 18066962697

💬 WhatsApp: +86 18066962697

🟢 WeChat: +86 18066962697

In the future, we will continue to deepen the research and development of composite processes, explore the composite application of more new functional materials (such as self-cleaning layers, light-guiding layers), and improve the customized service system to provide more WPC composite cladding products and solutions that meet the needs of high-end scenarios for global customers. We look forward to working with you to empower the upgrading of architectural decoration with innovative materials and jointly create high-quality projects with both functional value, aesthetic value and environmental protection value.

Get a Quote for Your Fencing Project Today